Welcome to our websites!

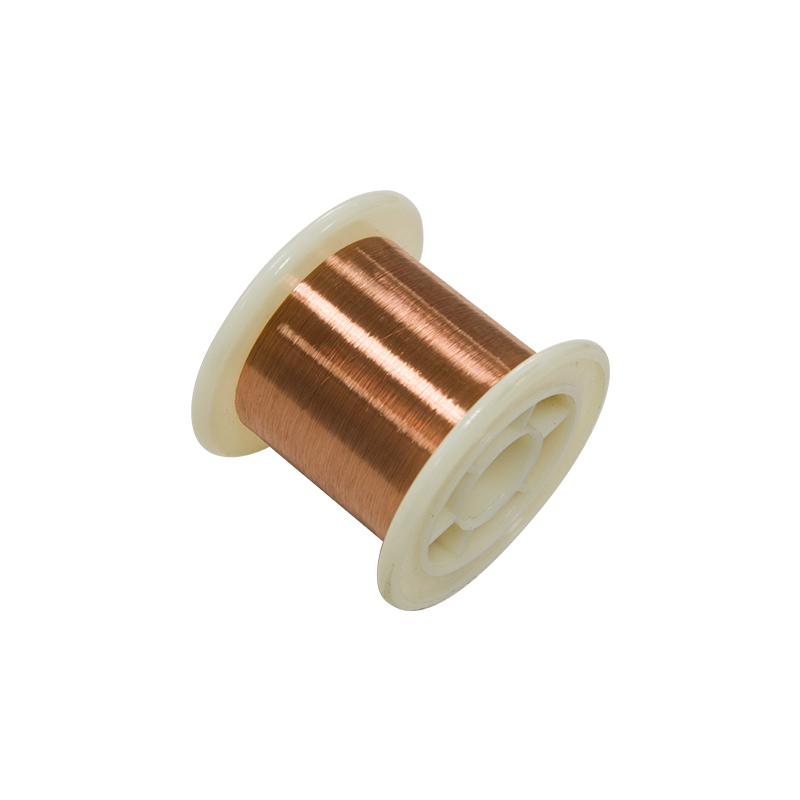

0.08mm fine Copper Nickel Alloy wire CuNi6 Cuprothal 10 UNS N04060 / 2.4816 for resistor

Copper Nickel Alloy is mainly made of copper and nickel. The copper and nickel can be melted together no matter what percentage. Normally the resistivity of CuNi alloy will be higher if the Nickel content is larger than Copper content. From CuNi6 to CuNi44, the resistivity is from 0.1μΩm to 0.49μΩm. That will help the resistor manufacture choosing the most suitable alloy wire.

Chemical Content, %

| Ni | Mn | Fe | Si | Cu | Other | ROHS Directive Cd | ROHS Directive Pb | ROHS Directive Hg | ROHS Directive Cr |

|---|---|---|---|---|---|---|---|---|---|

| 6 | - | - | - | Bal | - | ND | ND | ND | ND |

Mechanical Properties

| Property Name | Value |

|---|---|

| Max Continuous Service Temp | 200℃ |

| Resisivity at 20℃ | 0.1±10%ohm mm2/m |

| Density | 8.9 g/cm3 |

| Thermal Conductivity | <60 |

| Melting Point | 1095℃ |

| Tensile Strength, N/mm2 Annealed,Soft | 170~340 Mpa |

| Tensile Strength, N/mm2 Cold Rolled | 340~680 Mpa |

| Elongation(anneal) | 25%(Min) |

| Elongation(cold rolled) | 2%(Min) |

| EMF vs Cu, μV/ºC (0~100ºC) | -12 |

| Magnetic Property | Non |

Write your message here and send it to us