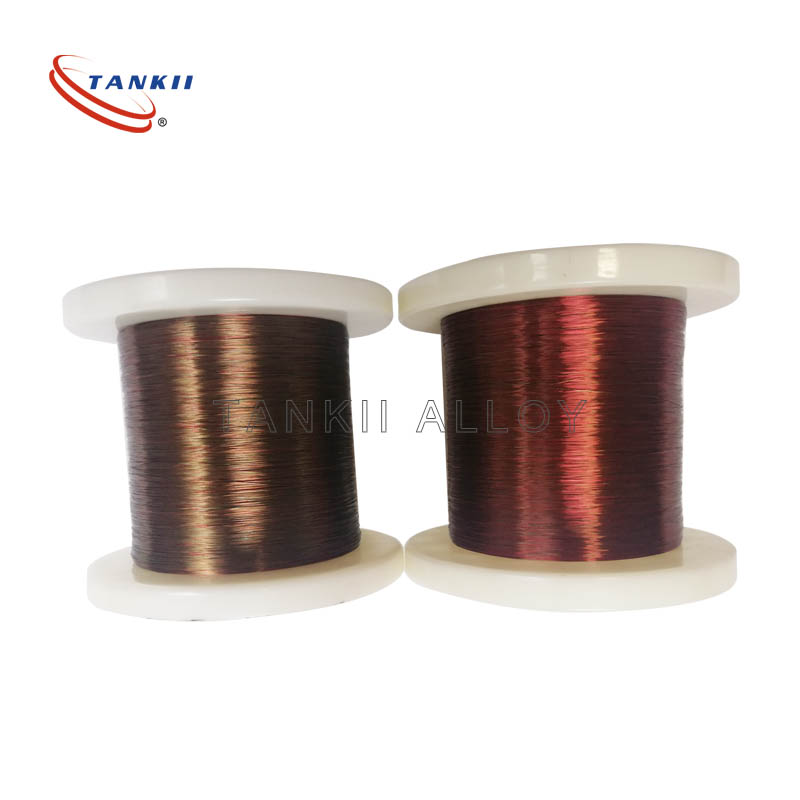

0.45mm Enameled Wire Electric Color Varnish Wire Polyurethane Smooth Surface

0.45mm Electric Color Varnish Wire Polyurethane Enameled Wire

Detailed Description

Polyurethane enameled wire lacquer was developed by Bayer in 1937. Because of its direct solderability, high frequency resistance and dyeability, it is widely used in electronics and electrical appliances. At present, foreign countries are very concerned about improving the heat resistance level of polyurethane enameled wire without affecting its direct welding performance. In Europe, the United States, and Japan, F-level and H-level polyurethane enameled wires have been developed. Due to the rapid development of color TVs, Japan’s color TV FBT with a large length of salt-free polyurethane enameled wire without pinholes has attracted the attention of countries around the world, and it is still Japan’s leading.

The alloy we can do enamelled are Copper-nickel alloy wire,Constantan wire,Manganin wire. Kama Wire,NiCr Alloy wire,FeCrAl Alloy wire etc alloy wire

Size:

Round wire:0.018mm~2.5mm

Color of enamel insulation:Red,Green,Yellow,Black,Blue,Nature etc.

Ribbon Size:0.01mm*0.2mm~1.2mm*5mm

Moq:5kg each size

Magnet wire or enameled wire is a copper or aluminium wire coated with a very thin layer of insulation. It is used in the construction of transformers, inductors, motors, generators, speakers, hard disk head actuators, electromagnets, electric guitar pickups and other applications that require tight coils of insulated wire.

The wire itself is most often fully annealed, electrolytically refined copper. Aluminium magnet wire is sometimes used for large transformers and motors. The insulation is typically made of tough polymer film materials rather than enamel, as the name might suggest.Enameled wire is a main variety of winding wire. It consists of two parts, the conductor and the insulation layer. The bare wire is annealed and softened, and then painted and baked multiple times. However, it is not easy to produce products that meet the requirements of the standard and meet the requirements of customers. It is affected by factors such as the quality of raw materials, process parameters, production equipment, and the environment. Therefore, the quality characteristics of various enameled wires are different, but all have Mechanical properties, chemical properties, electrical properties, and thermal properties.

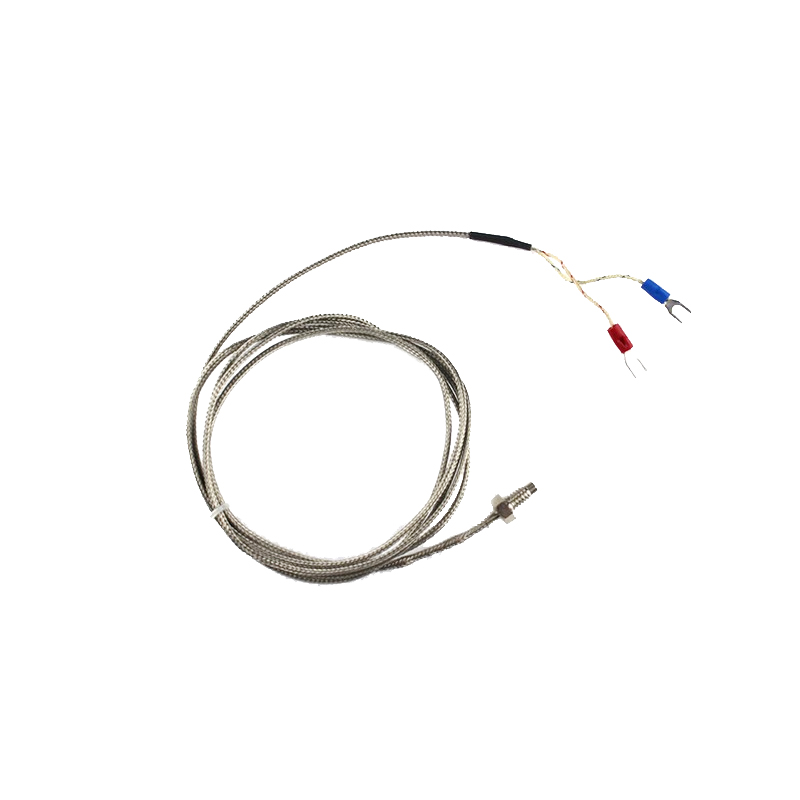

These enameled resistance wires have been broadly used for standard resistors, automobile

parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating.

Furthermore, we will carry out enamel coating insulation of precious metal wire such as silver and platinum wire upon order. Please make use of this production-on-order.

| Insulation-enamelled Name | Thermal Level℃

(working time 2000h) |

Code Name | GB Code | ANSI. TYPE |

| Polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| Polyester enamelled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled wire | 200 | EIWH

(DFWF) |

QZY/XY | MW35C |

| Polyamide-imide enamelled wire | 220 | AIW | QXY | MW81C

|