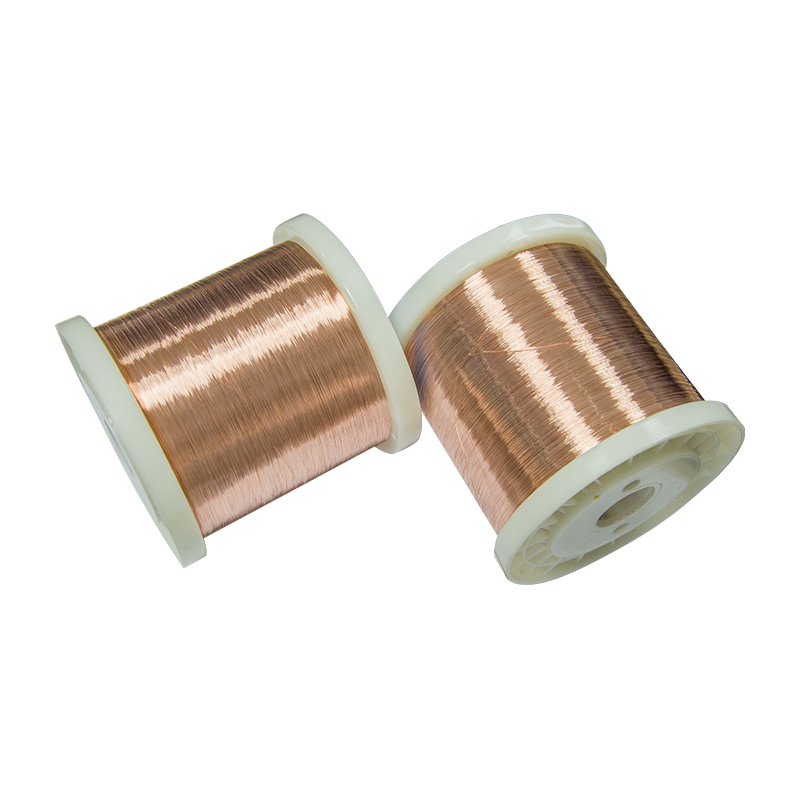

10 AWG Soldering Nickel Plated Copper Wire for Resistor Lead

Product Advantage:

1. The weldability is excellent; the ferrochrome soldering, wave soldering and reflow soldering can be arbitrarily satisfied.

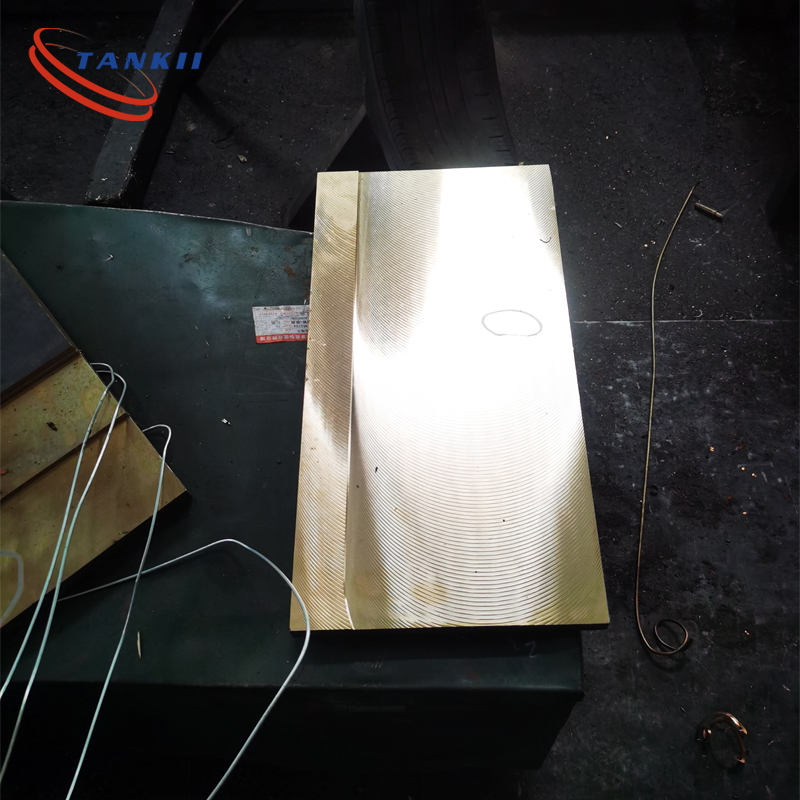

2. The plating is bright, smooth, uniform and moist; and the binding force and continuity is good.

3. The core of the wire is made up of high-quality 99.9% pure copper, which offers excellent electrical conductivity and thermal stability.

4. The outer layer consists of a nickel plating, which enhances the wire’s corrosion resistance, hardness, and durability.

5. Withstand harsh conditions, including high temperatures, vibrations, and mechanical stress, suitable for applications such as marine and automotive industries.

6. The mechanical properties can be privately customized, to ensure stable and reliable application in the different conditions.

Nickel Plated Copper Wire Characteristics:

| Nickel plated copper wire | |||

| Nominal diameter (d) | Permissible Variations in Diameter | ||

| mm | mm | ||

| 0.05≤d<0.25 | +0.008/-0.003 | ||

| 0.25≤d<1.30 | +3%d/-1%d | ||

| 1.30≤d≤3.26 | +0.038/-0.013 | ||

| Nominal diameter (d) | Tensile Requirements(Min. %) | Tensile Requirements(Min. %) | |

| mm | Classes 2, 4, 7 and 10 | Class 27 | |

| 0.05≤d≤0.10 | 15 | 8 | |

| 0.10<d≤0.23 | 15 | 10 | |

| 0.23<d≤0.50 | 20 | 15 | |

| 0.50<d≤3.26 | 25 | 20 | |

| Class, % Nickel | Electrical Resistivity Requirements | Conductivity | |

| Ω·mm²/mat 20°C(Min.) | % IACS at 20°C(Min.) | ||

| 2 | 0.017960 | 96 | |

| 4 | 0.018342 | 94 | |

| 7 | 0.018947 | 91 | |

| 10 | 0.019592 | 88 | |

| 27 | 0.024284 | 71 | |

| Thickness of Coating | |||

| The thickness of the nickel plating layer shall meet the standards of GB/T11019-2009 and ASTM B335-2016, and customers may have different requirements. |

|||