Welcome to our websites!

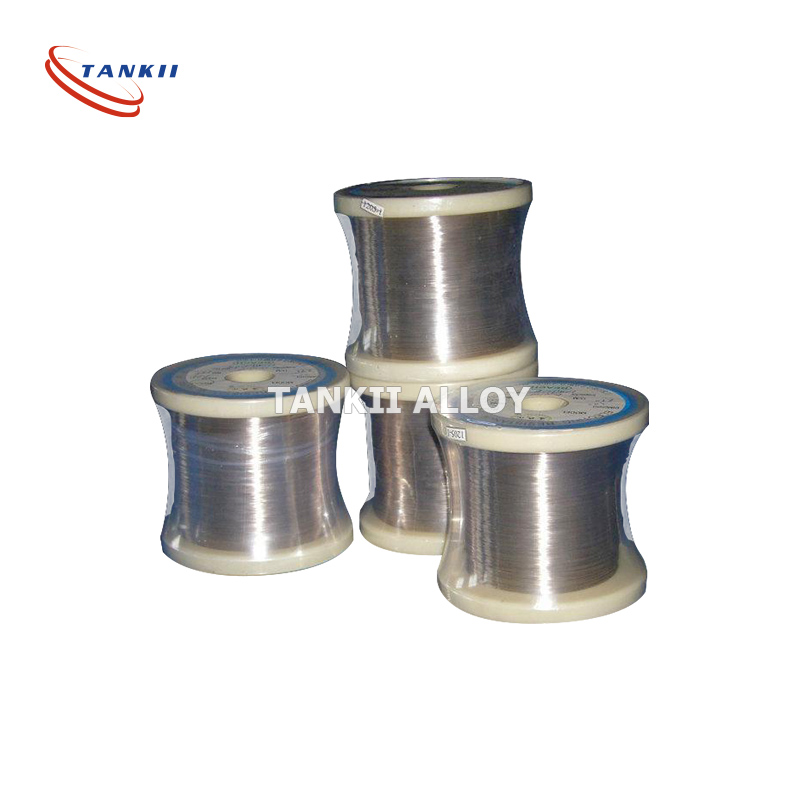

100% Original Porcupine Elements - 0Cr27Al7Mo2 1Cr13Al4 0Cr25Al5 fecral electric heating alloy wire – TANKII

100% Original Porcupine Elements - 0Cr27Al7Mo2 1Cr13Al4 0Cr25Al5 fecral electric heating alloy wire – TANKII Detail:

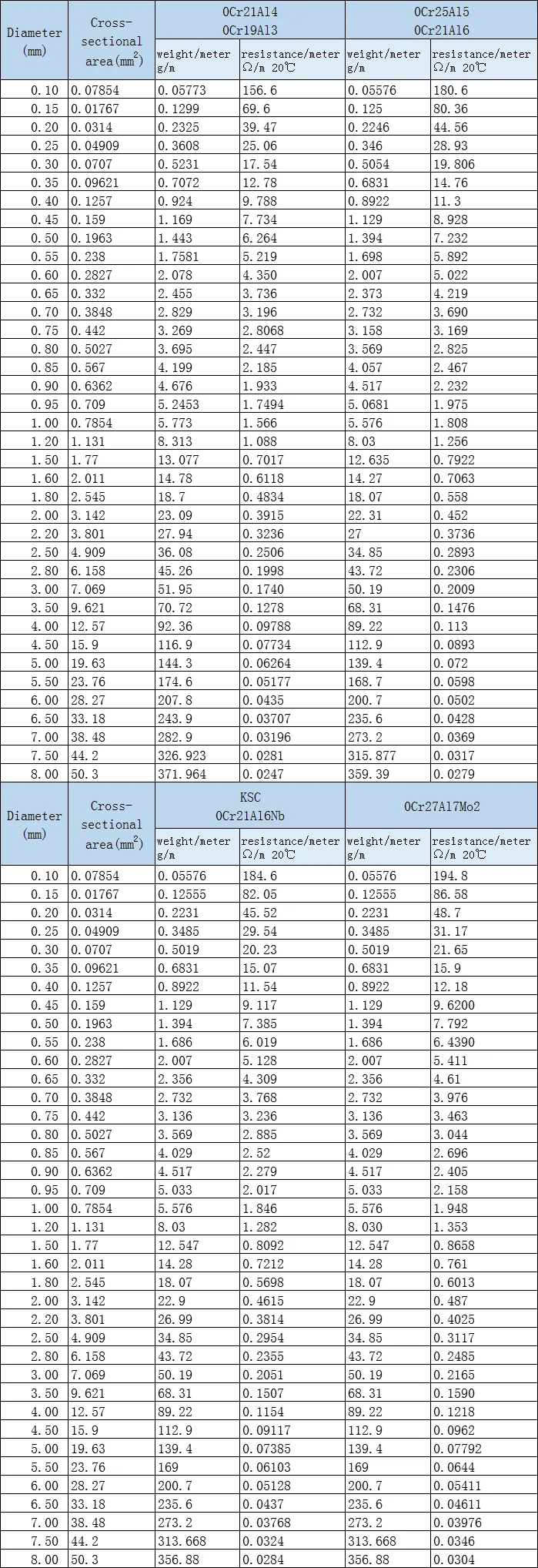

0Cr27Al7Mo2 0Cr13Al4 0Cr25Al5 fecral electric heating alloy wire

|

Grade

|

0Cr25Al5

|

|

Size

|

0.1-1.2mm

|

|

Surface

|

bright annealed

|

|

Weight

|

1-3kg/roll

|

|

Resistivity

|

1.42±0.07μΩ.m

|

|

Highest temperature

|

1250℃

|

|

Density

|

7.1g/cm³

|

|

Tensile strength

|

750N/mm²

|

|

Elongation

|

≥12%

|

|

Grade

|

Highest temperature

|

Resistivity

|

Melting point

|

Tensile strength

|

Elongation

|

|

0Cr21Al4

|

1100℃

|

1.23±0.06μΩ.m

|

1500℃

|

750

|

≥12

|

|

0Cr25Al5

|

1250℃

|

1.42±0.07μΩ.m

|

1500℃

|

750

|

≥12

|

|

0Cr23Al5

|

1300℃

|

1.35±0.06μΩ.m

|

1500℃

|

750

|

≥12

|

|

0Cr21Al6NbCo

|

1350℃

|

1.43±0.07μΩ.m

|

1510℃

|

750

|

≥12

|

|

0Cr27Al7Mo2

|

1400℃

|

1.53±0.07μΩ.m

|

1520℃

|

750

|

≥10

|

|

KSC

|

1350℃

|

1.44±0.05μΩ.m

|

1510℃

|

750

|

≥16

|

|

Cr20Ni80

|

1200℃

|

1.09±0.05μΩ.m

|

1400℃

|

750

|

≥20

|

|

Cr15Ni60

|

1150℃

|

1.12±0.05μΩ.m

|

1390℃

|

750

|

≥20

|

|

Cr20Ni35

|

1100℃

|

1.04±0.05μΩ.m

|

1390℃

|

750

|

≥20

|

|

Cr20Ni30

|

1100℃

|

1.04±0.05μΩ.m

|

1390℃

|

750

|

≥20

|

|

Grade

|

Chemical composition%

|

||||||||

|

C

|

P

|

S

|

Mn

|

Si

|

Cr

|

Ni

|

Al

|

Fe

|

|

|

≤

|

|||||||||

|

0Cr21Al4

|

0.12

|

0.025

|

0.025

|

0.7

|

≤1.0

|

17-21

|

≤0.6

|

3-4

|

balance

|

|

0Cr25Al5

|

0.06

|

0.025

|

0.02

|

0.5

|

≤0.6

|

23-26

|

≤0.6

|

4.5-6.5

|

balance

|

|

0Cr23Al5

|

0.06

|

0.025

|

0.02

|

0.5

|

≤0.6

|

20.5-23.5

|

≤0.6

|

4.2-5.3

|

balance

|

|

0Cr21Al6Nb

|

0.05

|

0.025

|

0.02

|

0.5

|

≤0.6

|

21-23

|

≤0.6

|

5-7

|

balance

|

|

0Cr27Al7Mo2

|

0.05

|

0.025

|

0.02

|

0.2

|

≤0.4

|

26.5-27.8

|

≤0.6

|

6-7

|

balance

|

|

Cr20Ni80

|

0.08

|

0.02

|

0.015

|

0.6

|

0.75-1.6

|

20-23

|

balance

|

<0.5

|

≤1.0

|

|

Cr15Ni60

|

0.08

|

0.02

|

0.015

|

0.6

|

0.75-1.6

|

15-18

|

55-61

|

<0.5

|

balance

|

|

Cr20Ni35

|

0.08

|

0.02

|

0.015

|

1.0

|

1-3

|

18-21

|

34-37

|

-

|

balance

|

|

Cr20Ni30

|

0.08

|

0.02

|

0.015

|

1.0

|

1-3

|

18-21

|

30-34

|

-

|

balance

|

Recommend Products

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for 100% Original Porcupine Elements - 0Cr27Al7Mo2 1Cr13Al4 0Cr25Al5 fecral electric heating alloy wire – TANKII , The product will supply to all over the world, such as: Tunisia, Sydney, Albania, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

Write your message here and send it to us