2020 China New Design Radiant Tube Bayonets - Tankii Focus On Customized High-End Hot Runner Heater Injection Molding Machine Heating Elements – TANKII

2020 China New Design Radiant Tube Bayonets - Tankii Focus On Customized High-End Hot Runner Heater Injection Molding Machine Heating Elements – TANKII Detail:

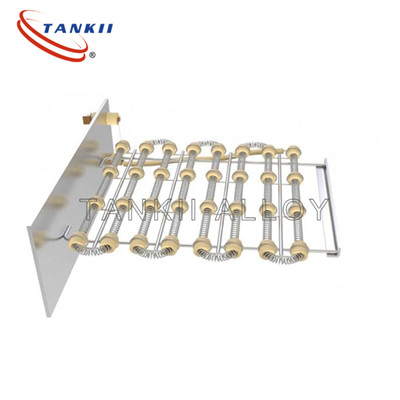

Bayonet heating elements are a reliable and efficient solution for electric heating applications.

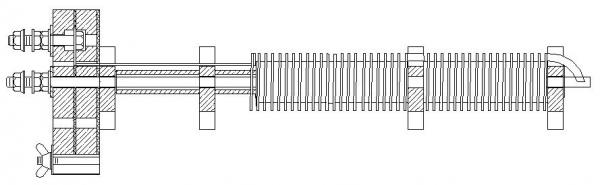

These elements are custom designed for the voltage and input (KW) required to satisfy the application. There are a wide variety of configurations available in either large or small profiles. Mounting can be vertical or horizontal, with heat distribution selectively located according to the required process. Bayonet elements are designed with ribbon alloy and watt densities for furnace temperatures up to 1800°F (980°C).

Advantages

· Element replacement is fast and easy. Element changes can be made while the furnace is hot, following all plant safety procedures. All electrical and replacement connections can be made outside the furnace. No field welds are necessary; simple nut and bolt connections allow for quick replacements. In some cases, replacement can be completed in as little as 30 minutes depending on the size of the element complexity and accessibility.

· Each element is custom designed for peak energy efficiency. Furnace temperature, voltage, desired wattage and material selection are all used in the design process.

· Inspection of the elements can be performed outside the furnace.

· When necessary, as with a reducing atmosphere, bayonets can be operated in sealed alloy tubes.

· Repairing a SECO/WARWICK bayonet element may be an economical alternative. Consult us for current pricing and repair options.

Bayonet heating element uses range from heat treat furnaces and die casting machines to molten salt baths and incinerators. They are also useful in converting gas-fired furnaces to electric heating.

- Broad power and temperature range

- Far higher power output than conventional heating element

- Excellent high temperature performance

- Long service life at all temperatures

Bayonet Heating Elements

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for 2020 China New Design Radiant Tube Bayonets - Tankii Focus On Customized High-End Hot Runner Heater Injection Molding Machine Heating Elements – TANKII , The product will supply to all over the world, such as: Lahore, Ukraine, Birmingham, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!