420SS Thermal Spray Wire for Arc Spraying: High-Performance Coating Solution

Product Description for 420 SS Thermal Spray Wire for Arc Spraying

Product Introduction

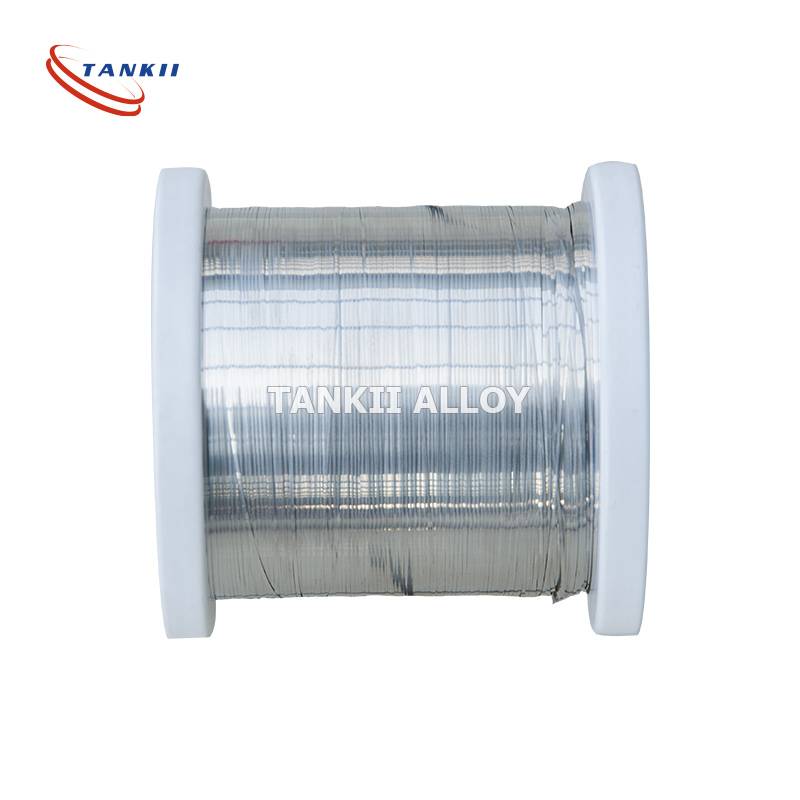

420 SS (Stainless Steel) thermal spray wire is a high-quality material designed for arc spraying applications. Known for its excellent corrosion resistance, high hardness, and good wear resistance, 420 SS is a martensitic stainless steel that provides robust surface protection. This wire is commonly used in industries such as petrochemical, power generation, automotive, and marine to enhance the durability and lifespan of critical components. The 420 SS thermal spray wire is ideal for applications requiring a hard, wear-resistant coating with moderate corrosion resistance.

Surface Preparation

Proper surface preparation is crucial to achieving optimal results with 420 SS thermal spray wire. The surface to be coated should be meticulously cleaned to remove contaminants such as grease, oil, dirt, and oxides. Grit blasting with aluminum oxide or silicon carbide is recommended to achieve a surface roughness of 50-75 microns. A clean and roughened surface enhances the adhesion of the thermal spray coating, leading to improved performance and longevity.

Chemical Composition Chart

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.15 – 0.40 |

| Chromium (Cr) | 12.0 – 14.0 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Iron (Fe) | Balance |

Typical Characteristics Chart

| Property | Typical Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1450°C |

| Hardness | 50-58 HRC |

| Bond Strength | 55 MPa (8000 psi) |

| Oxidation Resistance | Good |

| Thermal Conductivity | 24 W/m·K |

| Coating Thickness Range | 0.1 – 2.0 mm |

| Porosity | < 3% |

| Wear Resistance | High |

420 SS thermal spray wire is an excellent solution for enhancing the surface properties of components exposed to wear and moderate corrosion. Its high hardness and good wear resistance make it suitable for applications requiring a durable and long-lasting coating. By using 420 SS thermal spray wire, industries can significantly improve the service life and reliability of their equipment and components.