Welcome to our websites!

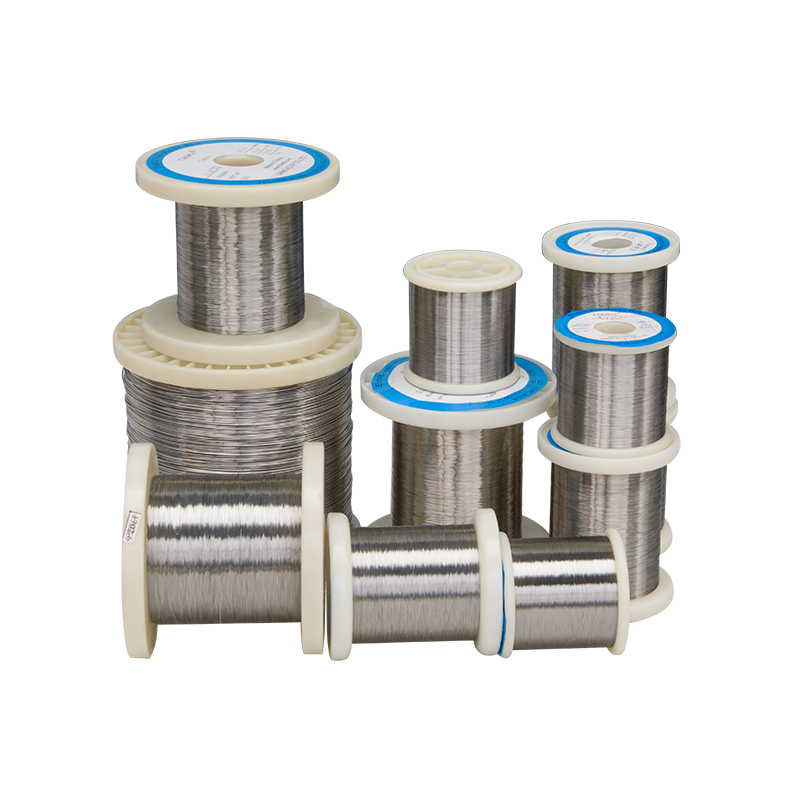

47HXP 47HX Glass Sealed Alloy Wire

Chemical Composition in %, Invar

| brand | Chemical composition | |||||||||

| Ni | Cr | Fe | C | P | Mn | B | Al | Si | S | |

| ≤ | ||||||||||

| 4j6 | 41.5~42.5 | 5.4~0~6.3 | Bal | 0.05 | 0.02 | 0.25 | - | 0.2 | 0.3 | 0.02 |

| 4j47 | 46.8~47.8 | 0.8~1.4 | Bal | 0.05 | 0.02 | 0.40 | - | - | 0.3 | 0.02 |

| 47HXP | 46.0~48.0 | 5.0~6.0 | Bal | 0.05 | 0.02 | 0.40 | 0.02 | - | 0.3 | 0.02 |

Basic physical constants and mechanical properties of the alloy:

| brand | Density g / cm3 | resistivity | Curie point |

| 4j6 | 8.15 | 0.92 | 270 |

| 4j47 | 8.19 | 0.55 | 400 |

| 47HXP | 8.18 | 0.90 | 340 |

coefficient of linear expansion

| Typical expansion character(10 -6 / ºC ) | |||||||

| Temperature range | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 | 20~550 | 20~600 |

| Expansion coefficient | 9.0 | 9.0 | 8.9 | 9.6 | 10.9 | 11.4 | 111.8 |

| Varieties | Steel typeSpecifications mm |

Precision alloy |

Resistance Alloys for electrical heating | Super alloy | Welding wire | Corrosion resistant alloy |

|

| Rods | hot rolling rods | Φ8~38mm | available | available | available | ||

| Cold-drawn rods | ≤50mm | available | available | available | |||

| Forged rods | Φ38~350mm | available | available | available | |||

| Wires | Round wires | Φ0.3~8mm | available | available | available | available | available |

| Non-circle wires | Negotiation | available | available | available | |||

| Strips | Cold rolling | 0.15~4×200mm | available | available | available | available | |

| Hot rolling | 4~22×200mm | available | available | available | available | ||

| Plates | Cold rolling | 0.5~4×1000×2000mm | available | available | available | ||

| Hot rolling | 4~22×1000×2000mm | available | available | available | |||

| tubes | Φ4~63×0.5~5mm | available | available | ||||

| Executive standard: GB, GJB, HB, YB, ASTM, AMSE, negotiation and so on. | |||||||

FeNiCr alloy is glass sealed alloy FeNiCr departments on behalf of the brand.The group alloy via air factory use for a long time, stable performance.Mainly used for making all kinds of electric vacuum components, such as electronic tube anode caps, etc.That should be chosen in the application of matching expansion coefficient of glass and metal.In order to improve the sealing strength of metal and glass allows alloy containing aluminum, cerium.When the heat treatment, grain size is too big, should be avoided to ensure the strip with good deep drawing extension performance and air tightness.

Write your message here and send it to us