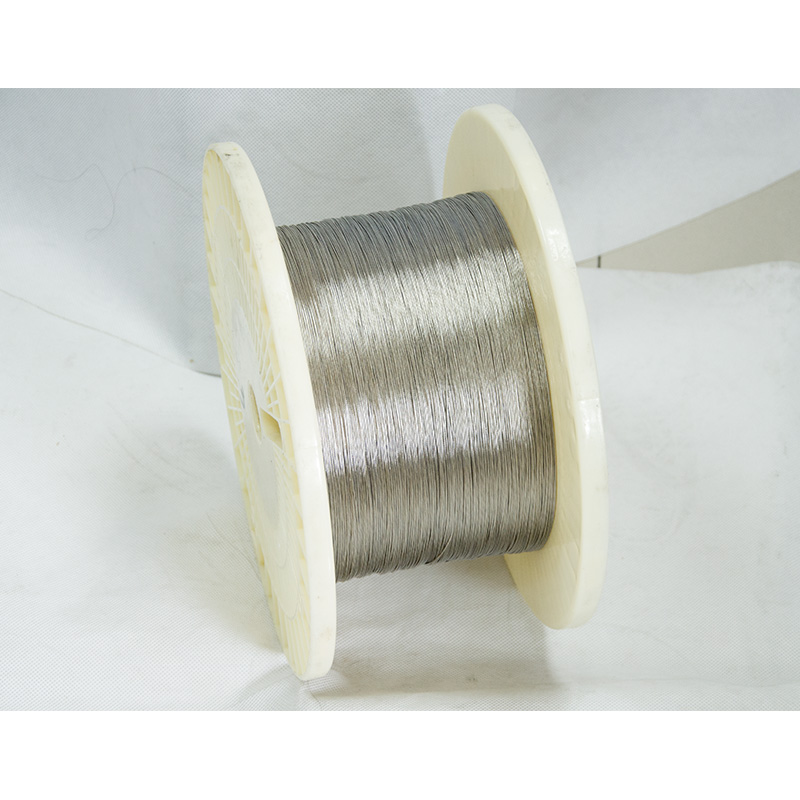

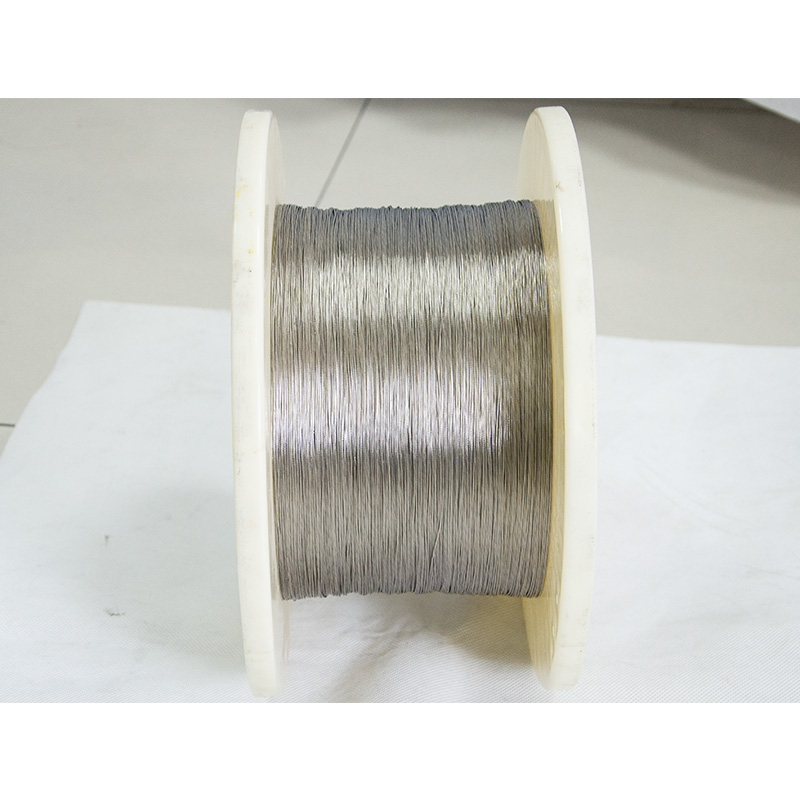

7 strands, 19 strands, or 37 strands Stranded Nichrome Wire

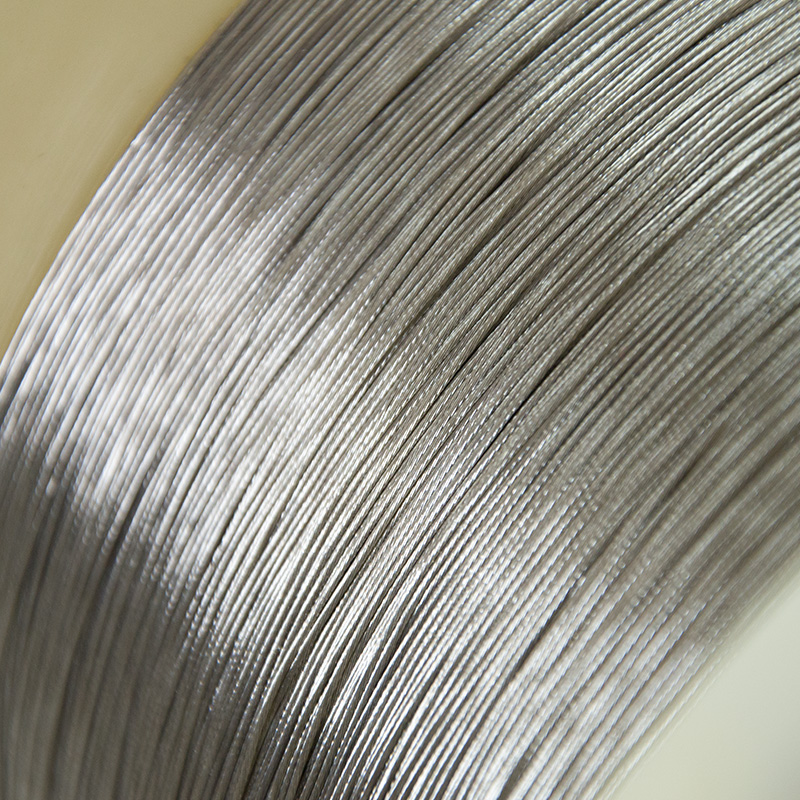

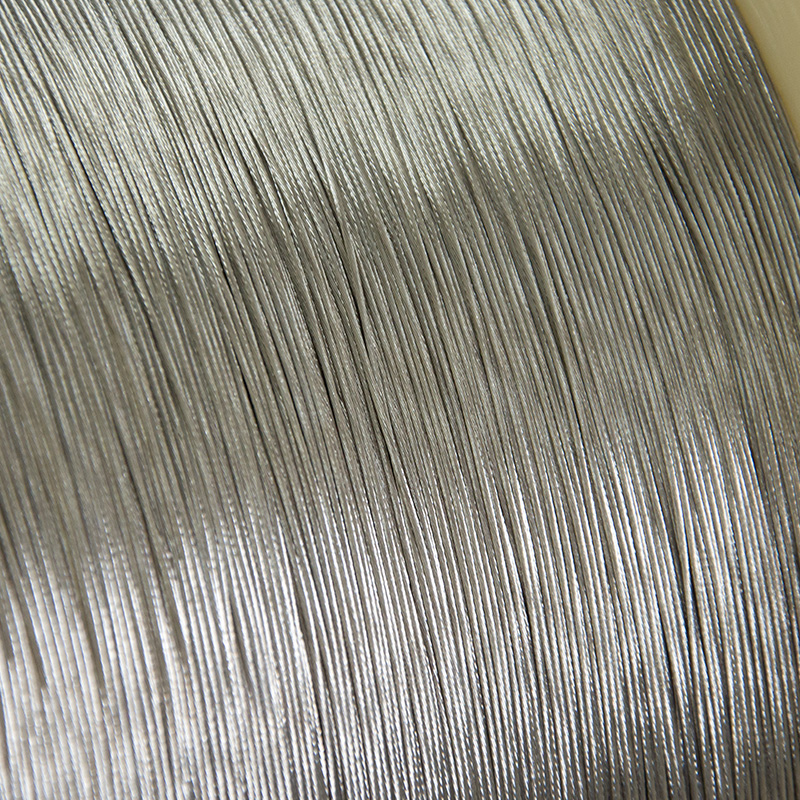

Stranded resistance wire is made of Nichrome alloys, such as Ni80Cr20, Ni60Cr15, etc. It can be made with 7 strands, 19 strands, or 37 strands, or other configurations.

Stranded resistance heating wire has many advantages, such as deformation ability, thermal stability, mechanical character, shockproof ability in thermal state and anti-oxidization. Nichrome Wire forms a protective layer of chromium oxide when it is heated for the first time. Material beneath the layer will not oxidize, preventing the wire from breaking or burning out. Due to Nichrome Wire’s relatively high resistivity and resistance to oxidation at high temperatures, it is widely used in heating elements, electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical and defense industries

|

Alloy |

Standard Strand Construction, mm |

Resistance,Ω/m |

Strand Diameter Nominal, mm |

Meter per Kilo |

|

NiCr 80/20 |

19×0.544 |

0.233-0.269 |

|

26 |

|

NiCr 80/20 |

19×0.61 |

0.205-0.250 |

|

|

|

NiCr 80/20 |

19×0.523 |

0.276-0.306 |

2.67 |

30 |

|

NiCr 80/20 |

19×0.574 |

|

2.87 |

25 |

|

NiCr 80/20 |

37×0.385 |

0.248-0.302 |

2.76 |

26 |

|

NiCr 60/15 |

19×0.508 |

0.286-0.318 |

|

|

|

NiCr 60/15 |

19×0.523 |

0.276-0.304 |

|

30 |