8 Year Exporter Stablohm 675 - Nickel Chrome Resistance Alloys – TANKII

8 Year Exporter Stablohm 675 - Nickel Chrome Resistance Alloys – TANKII Detail:

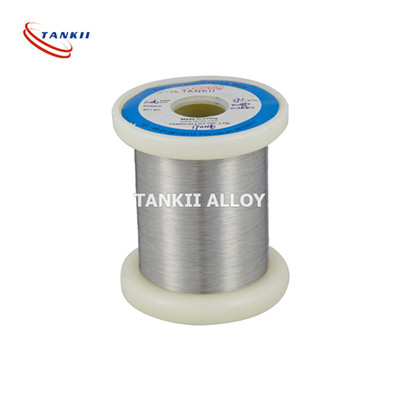

Nichrome, also known as nickel chrome, is an alloy produced by mixing nickel, chromium and, occasionally, iron. Best known for its heat resistance, as well as its resistance to both corrosion and oxidation, the alloy is incredibly useful for a number of applications. From industrial manufacturing to hobby work, nichrome in the form of wire is present in a range of commercial products, crafts and tools. It also finds applications in specialized settings.

Nichrome wire is an alloy made from nickel and chromium. It resists heat and oxidation and serves as a heating element in products such as toasters and hair dryers. Hobbyists use nichrome wire in ceramic sculpture and glassmaking. The wire can also be found in laboratories, construction and specialized electronics.

Because nichrome wire is so resistant to electricity, it is incredibly useful as a heating element in commercial products and home tools. Toasters and hair dryers use coils of nichrome wire to create large amounts of heat, as do toaster ovens and storage heaters. Industrial furnaces also use nichrome wire to function. A length of nichrome wire can also be used to create a hot wire cutter, which can be used either at home or in an industrial setting to cut and shape certain foams and plastics.

Nichrome wire is made of a non-magnetic alloy composed primarily of nickel, chromium, and iron. Nichrome is characterized by its high resistivity and good oxidation resistance. Nichrome wire also has good ductility after use and excellent weldability.

The number that comes after the Nichrome wire type indicates the percentage of nickel in the alloy. For example, “Nichrome 60″ has approximately 60% Nickel in its composition.

Applications for Nichrome wire include heating elements of hair dryers, heat sealers, and ceramic support in kilns.

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

Cr20Ni80 |

<0.50 |

1.09±0.05 |

850-950 |

>20 |

>9 |

1200 |

>20000 |

|

0.50-3.0 |

1.13±0.05 |

850-950 |

>20 |

>9 |

1200 |

>20000 |

|

|

>3.0 |

1.14±0.05 |

850-950 |

>20 |

>9 |

1200 |

>20000 |

|

|

Cr30Ni70 |

<0.50 |

1.18±0.05 |

850-950 |

>20 |

>9 |

1250 |

>20000 |

|

≥0.50 |

1.20±0.05 |

850-950 |

>20 |

>9 |

1250 |

>20000 |

|

|

Cr15Ni60 |

<0.50 |

1.12±0.05 |

850-950 |

>20 |

>9 |

1125 |

>20000 |

|

≥0.50 |

1.15±0.05 |

850-950 |

>20 |

>9 |

1125 |

>20000 |

|

|

Cr20Ni35 |

<0.50 |

1.04±0.05 |

850-950 |

>20 |

>9 |

1100 |

>18000 |

|

≥0.50 |

1.06±0.05 |

850-950 |

>20 |

>9 |

1100 |

>18000 |

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for 8 Year Exporter Stablohm 675 - Nickel Chrome Resistance Alloys – TANKII , The product will supply to all over the world, such as: Melbourne, Netherlands, Colombia, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.