Welcome to our websites!

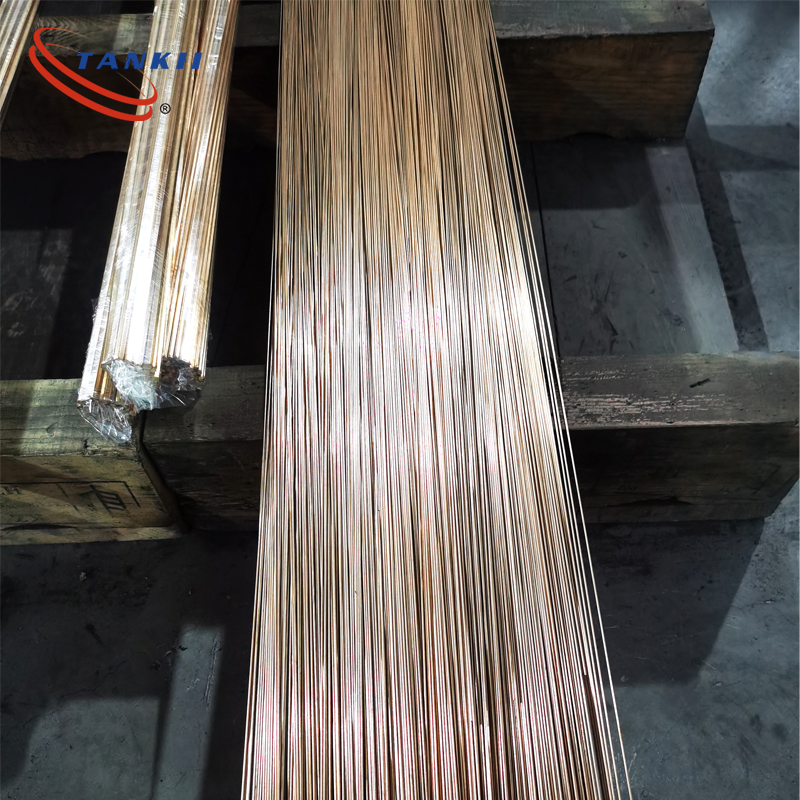

C17510 CuNi2be Copper Beryllium Round Bar for Valves Seats

Specification

UNS/CDA: UNS. C17510, CDA 1751

ASTM: B441

QQ/MIL: SAEJ 461,463

RWMA: Class 3

DIN: 2.0850, CW110C

UNS/CDA: UNS. C17510, CDA 1751

ASTM: B441

QQ/MIL: SAEJ 461,463

RWMA: Class 3

DIN: 2.0850, CW110C

Chemical Composition

Be:: 0.20-0.60%

Ni 1.40-2.20%

Cu:: Balance

Note:

Cu+Be+Co+Ni+Fe:99.50% Min.

Physical Properties

Ni 1.40-2.20%

Cu:: Balance

Note:

Cu+Be+Co+Ni+Fe:99.50% Min.

Physical Properties

|

Density (g/cm3)

|

0.317Ib/in3 at 68F

|

|

Specific Gravity

|

8.83g/cm3

|

|

Melting Point(Liquidus)

|

1955F

|

|

Melting Point(Solidus)

|

1885F

|

|

Electrical Resistivity

|

22.8 ohms/cmil/ft@68F

|

|

Electrical Conductivity

|

48%IACS@68F(heat-treated)

|

|

Thermal Conductivity

|

120.0Btu ft ata 68F

|

|

Modulus Elasticity inTension

|

19200ksi

|

Application

UNS.C17510 Beryllium Copper Alloy 3( CDA1751 DIN CuNi2Be 2.0850 CW110C)

Beryllium copper alloy C17510 is heat-treatable with moderate electrical and thermal conductivity and high tensile strength.

It is recommended for projection welding dies, flash and butt welding dies, current-carrying members, and heavy-duty offset electrode holders. It is also generally recommended for spot and steam welding steels with high electrical resistance, such as stainless steel.

It provide a good strength with even better thermal conductivity than C17200.This alloy offers conductivity of 45 to 60 percent of pure copper while providing significant strength and hardness properties. So C17510 is often used in the resistance welding industry

It is recommended for projection welding dies, flash and butt welding dies, current-carrying members, and heavy-duty offset electrode holders. It is also generally recommended for spot and steam welding steels with high electrical resistance, such as stainless steel.

It provide a good strength with even better thermal conductivity than C17200.This alloy offers conductivity of 45 to 60 percent of pure copper while providing significant strength and hardness properties. So C17510 is often used in the resistance welding industry

Write your message here and send it to us