China Cheap price Alloy 200 - Pure Nickel Wire N6 Nickel 201 Nickel 99.6 Wire for Lamp – TANKII

China Cheap price Alloy 200 - Pure Nickel Wire N6 Nickel 201 Nickel 99.6 Wire for Lamp – TANKII Detail:

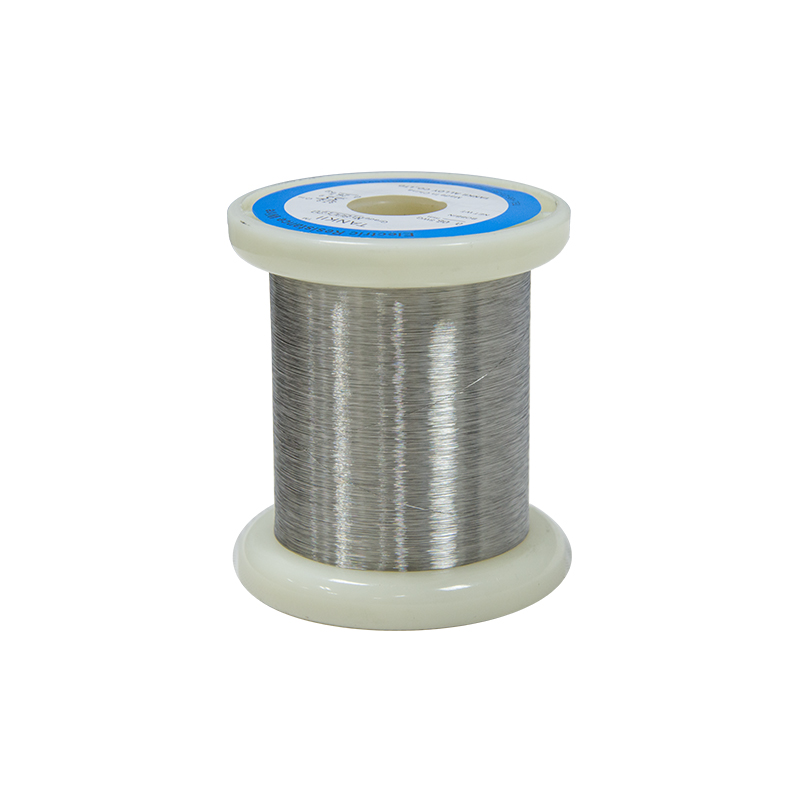

Pure Nickel Wire N6 Nickel 201 Nickel 99.6 Wire for Lamp

OHMALLOY 201

Common Name: N6, N4, Pure Nickel, Nickel 201

OHMALLOY200 are made by advanced vacuum melting process.and by forging,rolling,annealing and drawing. It is used in electric apparatus,lead for lamp and chemical machinery. Pure Nickel strip and foil, mainly used in batteries, electronic parts, some special lamp

1.Mechnical properties

| FORM | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Hardness (RB) | |

| Bar | Hot-finished | 105-310 | 60-85 | 55-35 | 45-80 |

| Cold-drawn,annealed | 105-210 | 55-75 | 55-40 | 75-98 | |

| Strip | Hard | 480-795 | 620-895 | 15-2 | >90 |

| Annealed | 105-210 | 380-580 | 55-40 | <70 | |

| Wire | Annealed | 105-345 | 380-580 | 50-30 | |

| No.1 Temper | 275-520 | 485-655 | 40-20 | ||

| Spring Temper | 725-930 | 860-1000 | 15-2 | ||

2. Physical properties

| Grade | Density (g/cm3) | Melting Range(ºC) | Curie point(ºC) | Volume resistivity (μΩ.cm) | Thermal conductivity (W/m. ºC) |

| Nickel 201 | 8.89 | 1435-1446 | 360 | 8.5(20ºC) | 79.3(20ºC) |

3.Chemical composition(%)

| Grade | C | Si | Mn | P | S | Ni+Co | Cu | Fe |

| Nickel 201 | <0.02 | <0.35 | <0.35 | <0.01 | >99.0 | <0.25 | <0.40 |

4.Specification

Strip:Thickness: 0.02mm to 3.0mm ,Width: 1.0mm to 250mm

Wire:Diameter: 0.025mm to 3.0mm

Sheet/Coil:Thickness:0.002-0.125mm

Width in coil:6.00mm max

In plate and straight lengths:12.00mm max

5.Usage

It is used in electric apparatus,lead for lamp and chemical machinery. Pure Nickel strip and foil, mainly used in batteries, electronic parts, some special lamp.

6.Features

Stable performance;Anti-oxidation;Corrosion resistance;High temperature stability;Excellent coil-forming ability;Uniform and beautiful surface condition without spots.

7.Packing detail

1) Coil (plastic spool) + compressed ply-wooden case + pallet

2) Coil (plastic spool) + carton + pallet

8.Products and services

1). Pass: ISO9001 certification, and SO14001cetification;

2). Fine after-sale services;

3). Small order accepted;

4). Stable properties in high temperature;

5). Fast delivery;

Shanghai Tankii Alloy Material Co., Ltd. Focus on the production of resistance alloy(nichrome Alloy, FeCrAl Alloy, copper nickel alloy, thermocouple wire, precision alloy and thermal spray alloy in the form of wire, sheet, tape, strip, rod and plate. We’ve already got ISO9001 quality system certificate and approval of ISO14001 environmental protection system. We own a complete set of advanced production flow of refining, cold reduction, drawing and heat treating etc. We also proudly have independent R&D capacity.

Shanghai Tankii Alloy Material Co., Ltd has accumulated lots of experiences over 35 years in this field. During these years, more than 60 management elites and high science and technology talents were employed. They participated in every walk of the company life, which make our company keep blooming and invincible in the competitive market. Based on the principle of “first quality, sincere service”, our managing ideology is pursuing technology innovation and creating the top brand in the alloy field. We persist in Quality – the foundation of the survival. It is our forever ideology to serve you with full heart and soul. We committed to provide customers all over the world with high-quality, competitive products and perfect service.

Our products, such us nichrome alloy, precision alloy, thermocouple wire, fecral alloy, copper nickel alloy, thermal spray alloy have been exported to over 60 countries in the world. We are willing to establish strong and long-time partnership with our customers. Most complete range of products dedicated to Resistance, Thermocouple and Furnace manufacturers Quality with end to end production control Technical support and Customer Service.

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for China Cheap price Alloy 200 - Pure Nickel Wire N6 Nickel 201 Nickel 99.6 Wire for Lamp – TANKII , The product will supply to all over the world, such as: Portugal, Egypt, Czech Republic, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.