China Cheap price Salt Baths - Tankii china supplier customized bayonet electric Heating Element with high quality and best price used in industry – TANKII

China Cheap price Salt Baths - Tankii china supplier customized bayonet electric Heating Element with high quality and best price used in industry – TANKII Detail:

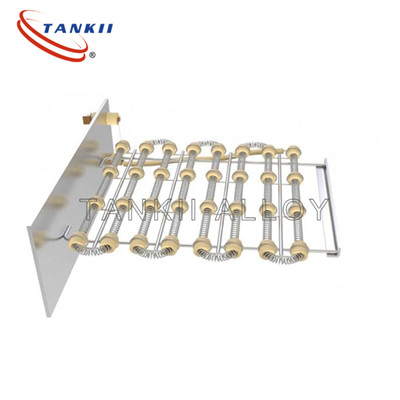

The bayonet-type heating element comprises more than two porcelains which are sequentially strung on a steel bar, wherein a first porcelain is provided with a wiring bar, a resistance band is winded between the first porcelain and a second porcelain; one end of the resistance band is connected with the wiring bar through the first porcelain, and the other end of the resistance band sequentially passes through other porcelains; the porcelains are round and each is provided with a square hole; and the resistance band is winded forming a cylinder. The beneficial effects of the utility model are that, bayonet-type heating elements are connected in parallel so as to ensure that while in use, if a bayonet-type heating element is damaged, the user can directly pull out the damaged element without blowing out the furnace, and a new element is directly inserted into the equipment for use; and the design facilitates the operation of the user, and effectively helps to complete the production.

Summary of the invention

Problem to be solved in the utility model provides a kind of bayonet type heating element, has solved the problem that exists when general heating element is installed, and is convenient to simultaneously change.

For solving the problems of the technologies described above, the technical solution adopted in the utility model is: the bayonet type heating element, comprise the porcelain piece more than 2, and described porcelain piece is passed rod iron successively; Be provided with the wiring rod in the first porcelain piece; Be wound with resistive band between the first porcelain piece and the second porcelain piece; Resistive band one end connects the wiring rod by the first porcelain piece, and the other end passes all the other porcelain pieces successively.

Further, described porcelain piece is circular and which is provided with the hole.

Further, described hole is square hole.

Further, described porcelain piece has 5.

Further, described resistive band is wound in cylindrical shape

Advantage and the good effect that the utlity model has are: owing to adopt technique scheme, can the resistive band and the external radiation pipe that twine is isolated, effectively avoided short circuit phenomenon.Simultaneously, the bayonet type heating element all is directly to be inserted into inside by the body of heater outside, and the hold-down mechanism by outside disk is fastened on the body of heater outside with it again.And parallel form is all adopted in the connection between every group, need to change even so just can guarantee in use to have a heating element to damage, the user also can directly extract the element that damages without blowing out, new element is directly inserted back in the equipment and can use, such design is not only convenient for users, simultaneously the more effective output of finishing also.

Description of drawings

Fig. 1 is structural representation of the present utility model.

1. bayonet type heating element, it is characterized in that: comprise the porcelain piece more than 2, described porcelain piece is passed rod iron (5) successively; Be provided with wiring rod (1) in the first porcelain piece (2); Be wound with resistive band (3) between the first porcelain piece (2) and the second porcelain piece; Resistive band (3) one ends connect wiring rod (1) by the first porcelain piece (2), and the other end passes all the other porcelain pieces successively.

2. bayonet type heating element according to claim 1 is characterized in that: described porcelain piece is circular and which is provided with the hole.

3. bayonet type heating element according to claim 2, it is characterized in that: described hole is square hole.

4. bayonet type heating element according to claim 1, it is characterized in that: described porcelain piece has 5.

5. bayonet type heating element according to claim 1, it is characterized in that: described resistive band (3) is wound in cylindrical shape.

Product detail pictures:

Related Product Guide:

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for China Cheap price Salt Baths - Tankii china supplier customized bayonet electric Heating Element with high quality and best price used in industry – TANKII , The product will supply to all over the world, such as: Cyprus, Sierra Leone, San Diego, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!