China wholesale Nickel 200 - Pure Nickel Wire (NI200 NI201) UNS NO2201 0.025mm – TANKII

China wholesale Nickel 200 - Pure Nickel Wire (NI200 NI201) UNS NO2201 0.025mm – TANKII Detail:

Pure Nickel Wire (NI200 NI201) UNS NO2201 0.025mm

| Nickel Grade | Ni+Co | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | Bal. | .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | Bal. | .25 | .3 | .35 | .15 | .2 | .01 | .3 | - |

Nickel wire

Characteristics and Applications of Nickel wire

1) High degree of electrical conductivity

2) Low electrical resistivity

3) Excellent surface and slit edge conditions

4) Enhanced solderability as a result of low surface oxides

5) Excellent formability with deep draw characteristics with reduced die wear

6) Resistance to grain growth

7)Rechargeable Batteries (Nickel Metal Hydride, Lithium Ion), Metal Stamping, 8)Lead Frames, Gaskets and Seals, Lighting Applications, Superconductor Applications

Nickel Strip Dimension Tolerance

| Thickness (mm) | Thickness Tolerance | Burr height |

Width Tolerance (mm) | |||||

| 2≤w <10 |

10≤w <50 |

50≤w <100 |

100≤w <150 |

150≤w <200 |

200≤w ≤500 |

|||

| 0.02≤t<0.05 | +0.002, -0.003 |

≤0.005 | ±0.05 | ±0.10 | ±0.15 | ±0.20 | ±0.30 | ±0.50 |

| 0.05≤t<0.1 | ±0.005 | ≤0.01 | ||||||

| 0.1≤t<0.2 | ±0.008 | ≤0.015 | ||||||

| 0.2≤t<0.3 | ±0.012 | ≤0.02 | ||||||

| 0.3≤t<0.4 | ±0.015 | ≤0.03 | ±0.10 | ±0.15 | ±0.25 | ±0.50 | ±0.80 | ±1.00 |

| 0.4≤t<0.6 | ±0.025 | ≤0.05 | ||||||

| 0.6≤t<0.8 | ±0.030 | ≤0.06 | ±0.30 | ±0.40 | ±0.50 | ±0.50 | ±0.80 | ±1.00 |

| 0.8≤t<1.0 | ±0.040 | |||||||

| 1.0≤t<1.2 | ±0.050 | ≤0.08 | ±0.50 | ±0.50 | ±0.80 | ±1.00 | ±1.00 | ±1.50 |

| 1.2≤t<1.4 | ±0.060 | |||||||

| 1.4≤t<1.7 | ±0.070 | ≤0.10 | ||||||

| 1.7≤t<2.0 | ±0.080 | |||||||

Applications of Nickel Wire

Eectric apparatus and chemical machinery,strong base of the filter ,valves grid, inner components of vacuum valves, components insides the electron tubes, lead

wire, supporting wire, battery production, vacuum coating, sparking electrodes, and heat exchangers

Shanghai Tankii Alloy Material Co., Ltd. is specialized in production of Ni-Cr Alloy, Cu-Ni Alloy, Fechral, thermocouple wire, pure nickel and other precision alloy materials in the form of wire, strip, rod, bar and plate.

Dimension and Tolerance (mm)

| Diameter | 0.025-0.03 | >0.03-0.10 | >0.10-0.40 | >0.40-0.80 | >0.80-1.20 | >1.20-2.00 |

| Tolerance | ±0.0025 | ±0.005 | ±0.006 | ±0.013 | ±0.02 | ±0.03 |

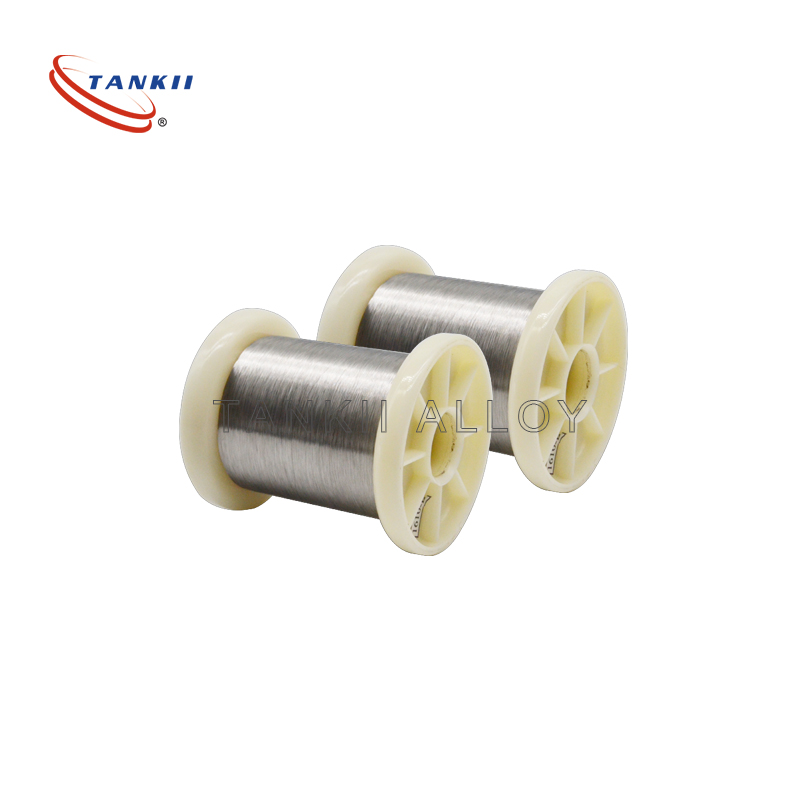

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for China wholesale Nickel 200 - Pure Nickel Wire (NI200 NI201) UNS NO2201 0.025mm – TANKII , The product will supply to all over the world, such as: Norwegian, Belarus, Saudi Arabia, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.