Welcome to our websites!

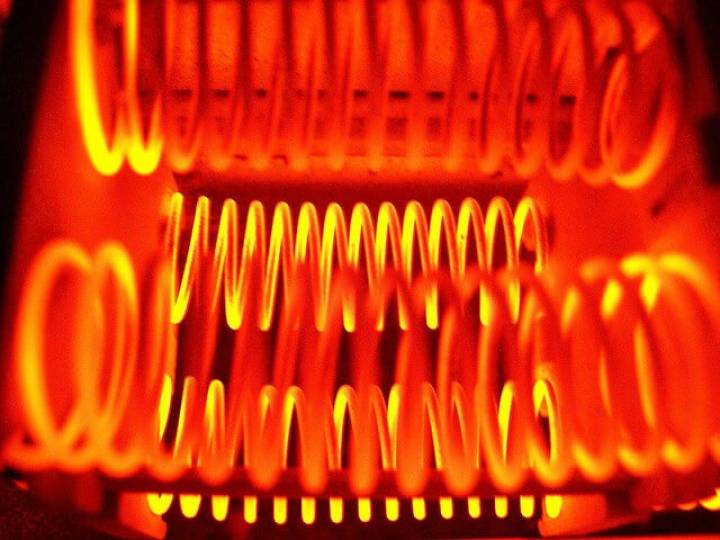

cr20ni30 electrical resistance wire for electric stove spring heating coil

heating cr20ni30 electrical resistance wire for electric stove

Main Property of heating resistance wire

| Type | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Main chemical composition | Ni | Rest | 55.0~61.0 | Rest | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Rest | ≤1 | Rest | Rest | |

| Maximal Temperature(℃) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Resistance Temperature correction coefficient.(CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Melting point (℃) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivityρ20℃(10-6Ω.m) | 800℃ | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000℃ | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200℃ | 1.025 | 1.043 | ||||

| Fast life value | Tem.(℃) | 1175 | 1100 | 1200 | 1050 | 1050 |

| hour(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Specific gravity(g/cm3) | 8.4 | 8.2 | 8.1 | 7.9 | 7.9 | |

| Elongation(%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Thermal(kj/m.h.℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Specific heat(20℃)j/g.℃ | 0.44 | 0.494 | 0.461 | 0.5 | 0.5 | |

| Extend strength(20~1000℃)α*10-6℃ | 18 | 17 | 17.1 | 19 | 19 | |

| Tensile strength(kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Repeatedly bending(F/R) | >12 | >12 | >12 | >12 | >12 | |

| Microstructure | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

| Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Thickness(mm) | Tolerance(mm) | Width(mm) | Tolerance(mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 |

±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Write your message here and send it to us