Electric Oven Wire Electric Stove Wire Industrial Electric Furnace Resistant Heat coil

Electric Oven Wire Electric Stove Wire Industrial Electric Furnace Resistant Heat Wire

General Information

Electric Oven Wire is a type of high resistance electrical wire. The wire resists the flow of electricity, and converts the electrical energy into heat.

Application for resistance wire includes resistors, heating elements, electric heaters, electric ovens, toasters, and many more.

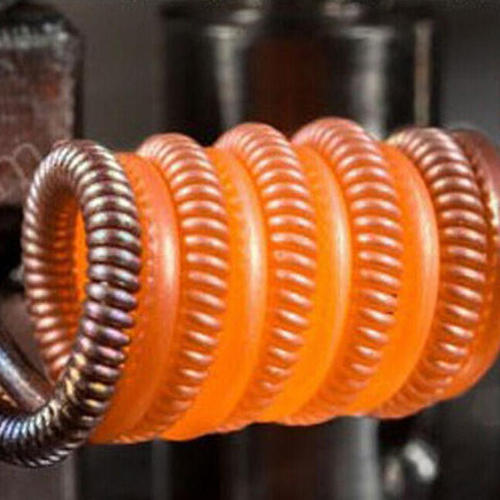

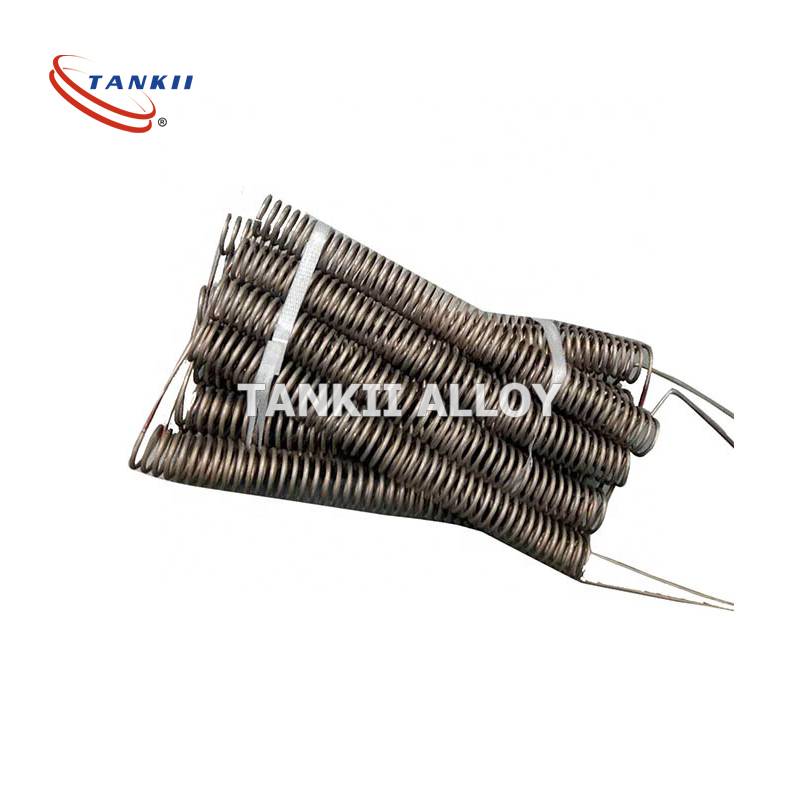

Nichrome, a non-magnetic alloy of nickel and chromium, is commonly used to make resistance wire because it has a high resistivity and resistance to oxidation at high temperatures. When used as a heating element, resistance wire is usually wound into coils. One difficulty in using Electric Oven Wire is that common electrical solder will not stick to it, so the connections to the electrical power must be made using other methods such as crimp connectors or screw terminals.

FeCrAl, a family of iron-chromium-aluminum alloys used in a wide range of resistance and high-temperature applications is also used in the form of resistance wires.

Characteristics & Properties

|

Material Designation |

Other Name |

Rough Chemical Composition |

|||||

|

Ni |

Cr |

Fe |

Nb |

Al |

Rest |

||

|

Nickel Chrome |

|||||||

|

Cr20Ni80 |

NiCr8020 |

80.0 |

20.0 |

||||

|

Cr15Ni60 |

NiCr6015 |

60.0 |

15.0 |

20.0 |

|||

|

Cr20Ni35 |

NiCr3520 |

35.0 |

20.0 |

45.0 |

|||

|

Cr20Ni30 |

NiCr3020 |

30.0 |

20.0 |

50.0 |

|||

|

Iron Chrome Aluminum |

|||||||

|

OCr25Al5 |

CrAl25-5 |

23.0 |

71.0 |

6.0 |

|||

|

OCr20Al5 |

CrAl20-5 |

20.0 |

75.0 |

5.0 |

|||

|

OCr27Al7Mo2 |

27.0 |

65.0 |

0.5 |

7.0 |

0.5 |

||

|

OCr21Al6Nb |

21.0 |

72.0 |

0.5 |

6.0 |

0.5 |

||

|

Material Designation |

Resistivity µOhms/cm |

Density G/cm3 |

Coefficient of Linear Expansion |

Thermal Conductivity W/m.K |

|

|

µm/m.°C |

Temp.°C |

||||

|

Nickel Chrome |

|||||

|

Cr20Ni80 |

108.0 |

8.4 |

17.5 |

20-1000 |

15.0 |

|

Cr15Ni60 |

112.0 |

8.2 |

17.5 |

20-1000 |

13.3 |

|

Cr20Ni35 |

105.0 |

8.0 |

18.0 |

20-1000 |

13.0 |

|

Iron Chrome Aluminum |

|||||

|

OCr25Al5 |

145.0 |

7.1 |

15.1 |

20-1000 |

16.0 |

|

OCr20Al5 |

135.0 |

7.3 |

14.0 |

20-1000 |

16.5 |

Suggested Applications

| Material Designation | Service Properties | Applications |

| Nickel Chrome | ||

| Cr20Ni80 | Contains long life additions making it eminently suitable for applications subject to frequent switching and wide temperature fluctuations. Can be used at operating temperatures up to 1150 °C. | Control resistors, high temperature furnaces, soldering irons. |

| Cr15Ni60 | A Ni/Cr alloy with balance mainly Iron, with long life additions. It is suitable for use up to 1100 °C, but the higher coefficient of resistance makes it suitable for less exacting applications than 80/20. | Electric heaters, heavy duty resistors, electric furnaces. |

| Cr20Ni35 | Balance mainly Iron. Suitable for continous operation up to 1050°C, in furnaces with atmospheres which may otherwise cause dry corrosion for higher nickel content materials. | Electric heaters, electric furnaces (with atmospheres). |

| Iron Chrome Aluminum | ||

| OCr25Al5 | Can be used in operating conditions up to 1350°C, although can become embrittled. | Heating elements of high temperature furnaces and radiant heaters. |

| OCr20Al5 | A ferromagnetic alloy which can be used at temperatures up to 1300°C. Should be operated in dry surroundings to avoid corrosion. Can become embrittled at high temperatures. | Heating elements of high temperature furnaces and radiant heaters. |