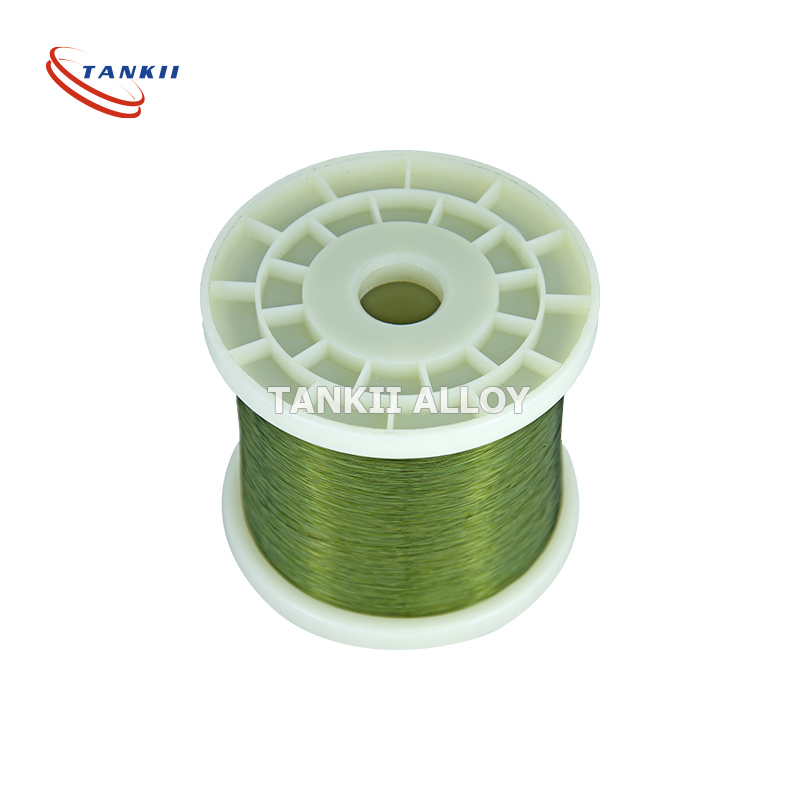

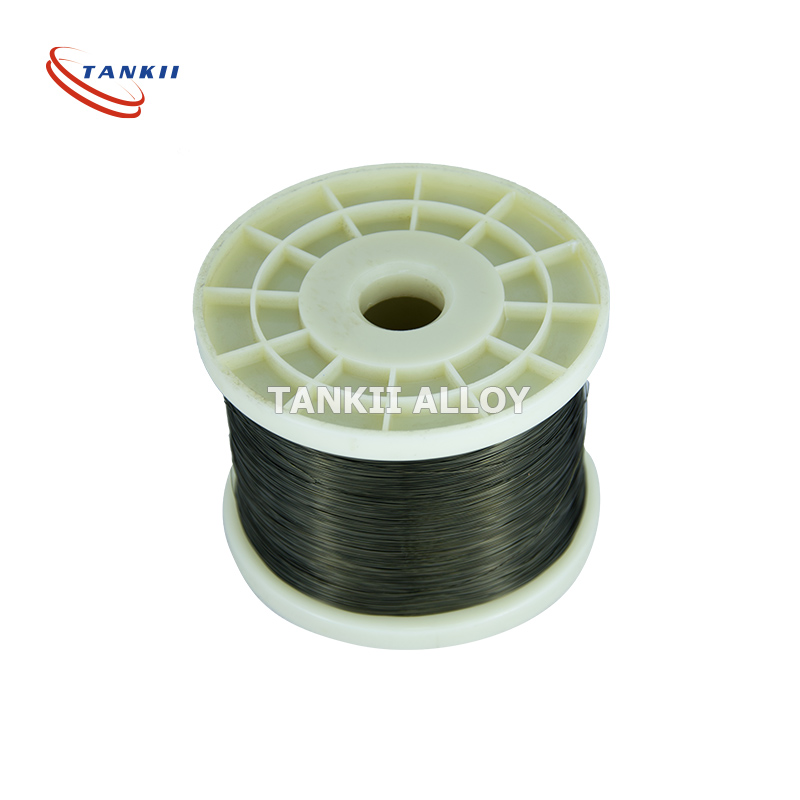

Enameled Copper manganin Wire Pure copper enameled wire

Enameled Copper Wire, otherwise known as winding wire or magnet wire, is a highly versatile material used principally in applications that require electrical transference including transformers, inductors, motors, generators, speakers, hard disk actuators, electromagnets and other applications that require tight coils of insulated wire.

Copper’s highly conductive properties make it the perfect metal for electrical applications, and it can be fully annealed and electrolytically refined to allow for closer winding for electromagnetic coils.

By coating the wire in insulation – typically one to four layers of polymer film – the wire is protected from contact with its own and other wire’s electrical currents, preventing short circuits from occurring and extending the longevity, efficiency and applications for the wire.

We can enamel constantan wire, nichrome wire, manganin wire, nickel wire, etc.

Mini enameled diameter mininum 0.01mm

Application: Use in Antenna inductance, high-power lighting systems, video equipment, ultrasonic equipment, high-frequency inductors and transformers, etc. High-frequency welding transformer lines, the company can produce all kinds of silk covered wire.

Multiple applications and uses

Enameled copper wire is used to convert electrical energy into other forms of energy across a wide range of applications.

For example, electric motors convert electrical energy into mechanical motion using magnetic fields and current-carrying conductors. Within an electric motor, to avoid energy loss through overheating and therefore lower efficiency, enamelled copper wire is used in the coils of the magnet, and copper itself is used throughout other components including brushes, bearings, collectors and connectors.

In transformers, enamelled copper wire is used in the transference of electricity from one circuit to another and can absorb additional stresses from mechanical vibration and centrifugal forces during operation. Copper wire offers the advantages of retaining tensile strength whilst being flexible and can be wound tighter and smaller than alternatives such as Aluminium, giving the copper wire a space-saving advantage.

In generators, there is a growing trend amongst manufacturers to produce equipment that operates at both higher temperatures and electrical conductivities, for which enamelled copper wire is an ideal solution.