Welcome to our websites!

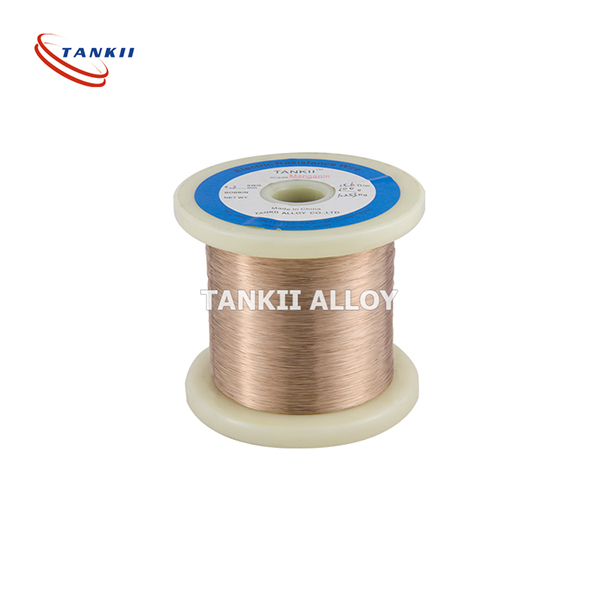

Enameled Manganin 43 Wire Dia 0.08mm CuMn12Ni Used for Precision Instrument

Chemical Composition:

| Name Code | Main Composition (%) | Cu | Mn | Ni |

| Manganin | CuMn12Ni | Bal | 11-13 | 2-5 |

Physical Properties:

| Name Code | Density (g/mm2) | Max. Working Temp.(º C ) |

| Manganin | 8.4 | 10-80 |

6Mechanical Properties:

|

Name |

Code | Resistivity (μ Ω. M) |

Temp. Coff. of Resistance (α×10-6/°C) |

Thermal EMF vs. Copper (μV/º C ) (0-100º C ) |

Elongation (%) | Tensile Strength(Mpa) |

| Manganin | 43 | 0.43 ±0.05 | 20 | ≤2 | ≥15 | 490–539 |

Application of Manganin

Manganin foil and wire is used in the manufacture of resistor, Particularly ammeter shunt, because of its virtually zero temperature coefficient of resistance value and long term stability.

Type of Insulation

| Insulation-enamelled Name | Thermal LevelºC

(working time 2000h) |

Code Name | GB Code | ANSI. TYPE |

| Polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| Polyester enamelled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled wire | 200 | EIWH

(DFWF) |

QZY/XY | MW35C |

| Polyamide-imide enamelled wire | 220 | AIW | QXY | MW81C |

Write your message here and send it to us