Enameled Manganin Wire /Insulated Manganin Wire (6J12 / 6J8/6J11/ 6J13)

Enameled Manganin Wire /Insulated Manganin Wire (6J12 / 6J8/6J11/ 6J13)

Material: CuNi1, CuNi2, CuNi4, CuNi6, CuNi8, CuNi14, CuNi19, CuNi23, CuNi30, CuNi34, CuNi44, constantan, manganin, karma in form of wire/ribbon

Chemical Content, %

| Ni | Mn | Fe | Si | Cu | Other | ROHS Directive | |||

| Cd | Pb | Hg | Cr | ||||||

| 2~3 | 11~13 | 0.5(max) | micro | Bal | - | ND | ND | ND | ND |

Mechanical Properties

| Max Continuous Service Temp | 0-45ºC |

| Resisivity at 20ºC | 0.47±0.03ohm mm2/m |

| Density | 8.44 g/cm3 |

| Thermal Conductivity | -3~+20KJ/m·h·ºC |

| Temp Coefficient of Resistance at 20 ºC | -2~+2α×10-6/ºC(Class0) |

| -3~+5α×10-6/ºC(Class1) | |

| -5~+10α×10-6/ºC(Class2) | |

| Melting Point | 1450ºC |

| Tensile Strength(Hard) | 635 Mpa(min) |

| Tensile Strength,N/mm2 Annealed,Soft | 340~535 |

| Elongation | 15%(min) |

| EMF vs Cu, μV/ºC (0~100ºC) | 1 |

| Micrographic Structure | austenite |

| Magnetic Property | non |

| Micrographic Structure | Ferrite |

| Magnetic Property | Magnetic |

Application of Manganin

Manganin foil and wire is used in the manufacture of resistor, Particularly ammeter shunt, because of its virtually zero temperature coefficient of resistance value and long term stability.

Common temperature classes are 130, 155, 180, 200, 220C

Enamelled Wire diameter: 0.02 mm~1.8mm round

Detailed Description Manganin foil and wire is used in the manufactur of resistor, particularly ammeter shunts, because of its virtually zero temperature coefficient of resistance value and long term stability.

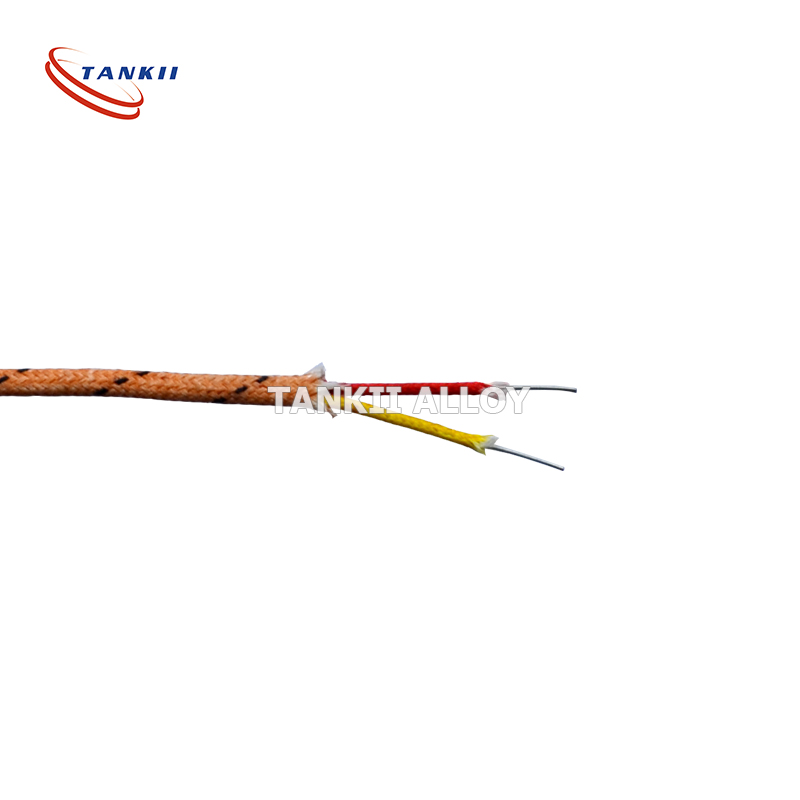

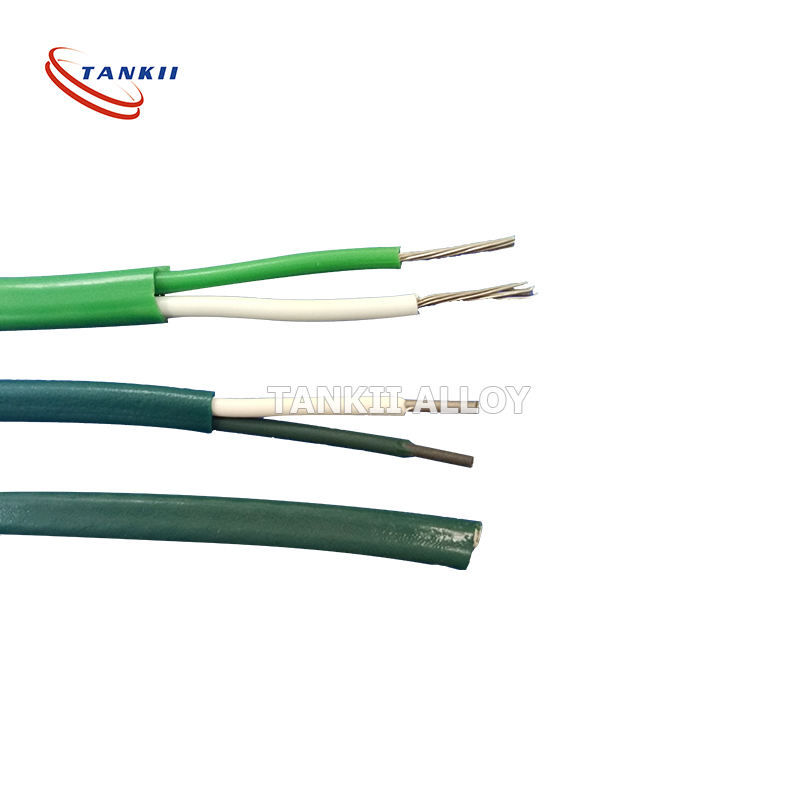

Enameled wire is a wire coated with a thin layer of insulation to prevent the wire surfaces from being in a short circuit when wound into coils. Magnetic flux is created when current flows through the coil. It is used mainly in the construction of motors, electromagnets, transformers and inductors. For ease of manufacturing inductive components like transformers and inductors, most of these wires can be soldered.

Enameled wires are classified by their diameter (AWG gauge number or millimetres), temperature class and insulation thickness. A thicker insulation layer results in a higher breakdown voltage (BDV). Common temperature classes are 130, 155, 180 and 200 ° C.

Due to the different characteristics of metal wire, wire enamelled coated with the different production processes, in the years of production practice, gradually we formed in the different needs of different materials coated enamelled techniques, especially in resistance wire, we can provide all kinds of production for resistance potentiometer constantan enameled wire, nichrome enameled wire, and kamar enameled wire, etc. We also in platinic gold, silver, gold plating coating on a successful experience in production. We can customize various special metal wire enameled wire. Its purpose is not confined to the resistance and the potentiometer production materials, such as sensors, etc.