Welcome to our websites!

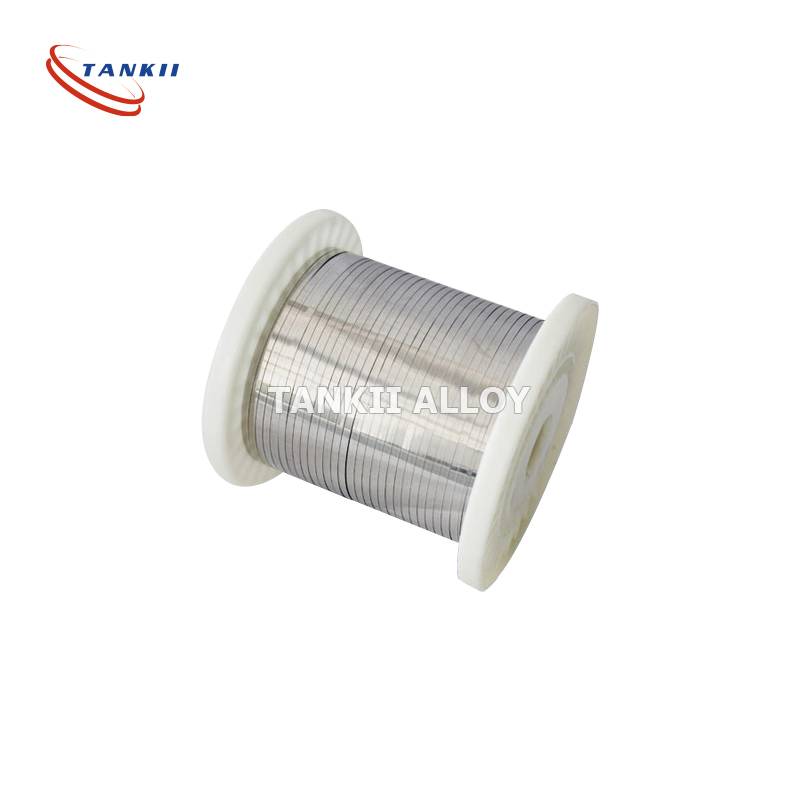

FeCrAl Alloy A1 Kan-thal APM Resisstance Heating Wire for Kilns

MAIN CHEMICAL ELEMENTS AND PROPERTIES

|

Properties \ Grade |

A1 |

||||||||||||||||

|

Cr |

Al |

Re |

Fe |

||||||||||||||

|

25.0 |

6.0 |

Suitable |

Balance |

||||||||||||||

|

Max Continuous Service Temperature(ºC) |

Diameter 1.0-3.0 |

Diameter large than 3.0, |

|||||||||||||||

|

1225-1350℃ |

1400℃ |

||||||||||||||||

|

Resisivity 20ºC (ohm*mm2/m) |

1.45 |

||||||||||||||||

|

Density(g/cm3) |

7.1 |

||||||||||||||||

|

Approximate Melting Point( ºC) |

1500 |

||||||||||||||||

|

Elongation (%) |

16-33 |

||||||||||||||||

|

Repeatedly Bend Frequency(F/R) 20℃ |

7-12 |

||||||||||||||||

|

Continuous Service Time 1350 ℃ |

More than 80 hours |

||||||||||||||||

|

Micrographic Structure |

Ferrite |

||||||||||||||||

| Furnace | Dry Air | Humid Air | hydrogen-argon | Argon | Decomposition | ||||||||||||

| atmosphere | gas | ammonia gas | |||||||||||||||

| Temp(℃) | 1400 | 1200 | 1400 | 950 | 1200 | ||||||||||||

User Manual

- Rated Voltage: 220V/380V

- The installation process to avoid knocking, to avoid the damp, hand-held stove wire, they should wear gloves. Wire should be installed after the furnace has remained flat, and prevent surface scratches, dirt, corrosion, or improper installation, by affecting the life of

- In the rated voltage to use. In strong reducing atmosphere, acid atmosphere, an atmosphere of high humidity will affect the use of life;

- Temperature before use should be in dry non-corrosive atmosphere, about 1000 ℃ spend a few hours, so that furnace wire protective film formed on the surface after normal use, so that can guarantee the normal life of furnace wire;

- Furnace installation should ensure that the insulated wire good power to avoid touching furnace after the wire, guard against electric shock or burns.

Write your message here and send it to us