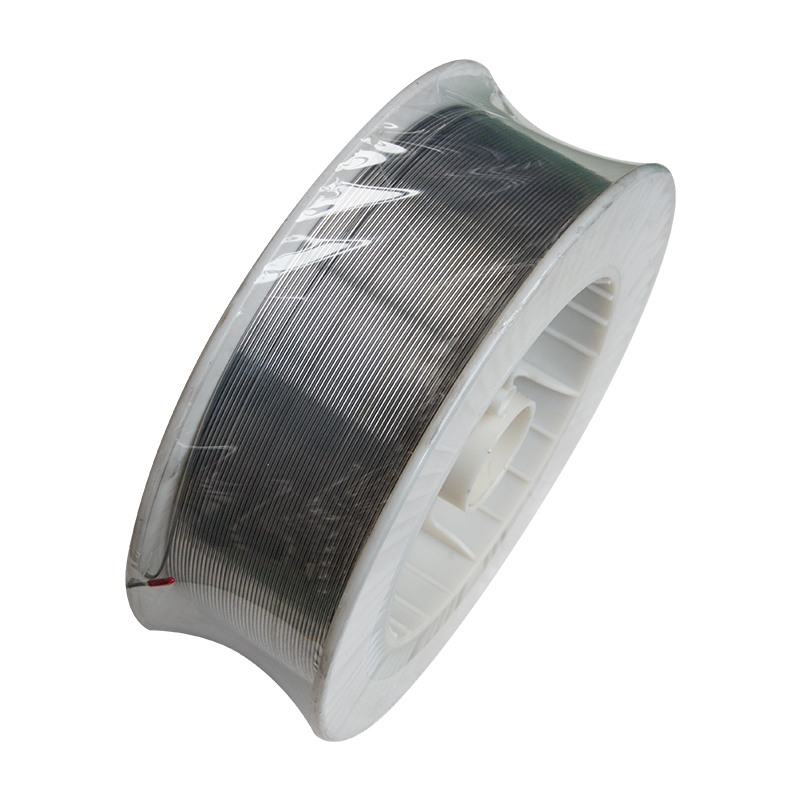

Gas Shielded Arc Copper Free Welding Wire Er70s-6, Sg2 Welding Wire

Introduction of Copper free welding wire:

After the application of active nanometer technology,the surface of the non-coppered welding wire is free from copper scale and more stable in wire feeding,which is more suitable in the filed of welding by automatic robot especially.The arc is featured by more stable stability,less spatter,less wear of current contact nozzle and greater depth of welding deposition.The working environment of the workers is greatly improved because the non-coppered welding wire is free from copper smoke.Due to the development of treatment method for the new surface,the non-coppered welding wire surpasses the coppered one in anti-rust property,with the following features.

1.very stable arc.

2. Fewer spatter particles

3.Superior wire-feeding property.

4.Good arc restriking

5.Good anti-rust property at the surface of of welding wire.

6.No generation of copper smoke.

7. Less wear of current contact nozzle.

Precautions:

1. Welding process parameters affect the mechanical properties of the weld metal, and the user should perform welding process qualification and reasonably select welding process parameters.

2. The rust, moisture, oil, dust and other impurities in the welding area should be strictly removed before welding.

Specifications: Diameter : 0.8mm,0.9mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm

Packing size: 15kg/20 kg per spool.

Typical Chemical composition of the welding wire(%)

==========================================

| Element | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

| Requirement | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

| Actual AVG Result | 0.08 | 1.45 | 0.85 | 0.007 | 0.013 | 0.018 | 0.034 | 0.06 | 0.012 | 0.28 |

Typical Mechanical properties of deposited metal

========================================

| Test Item | Tensile strength Rm(Mpa) |

Yield strength Rm(Mpa) |

Elongation A(%) |

V model Bump Test | |

| Test Temp (ºC) |

Impact Value (J) |

||||

| Requirements | ≥500 | ≥420 | ≥22 | -30 | ≥27 |

| Actual AVG Result | 589 | 490 | 26 | -30 | 79 |

Size and Recommended current range.

===============================

| Diameter | 0.8mm | 0.9mm | 1.0mm | 1.2mm | 1.6mm | 1.6mm |

| Amps | 50-140 | 50-200 | 50-220 | 80-350 | 120-450 | 120-300 |