Welcome to our websites!

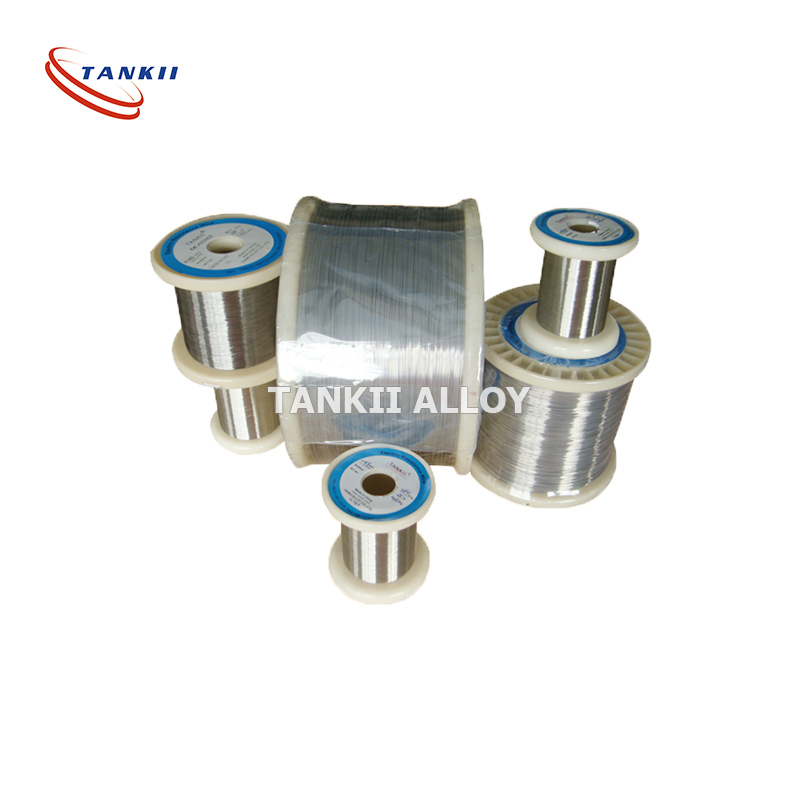

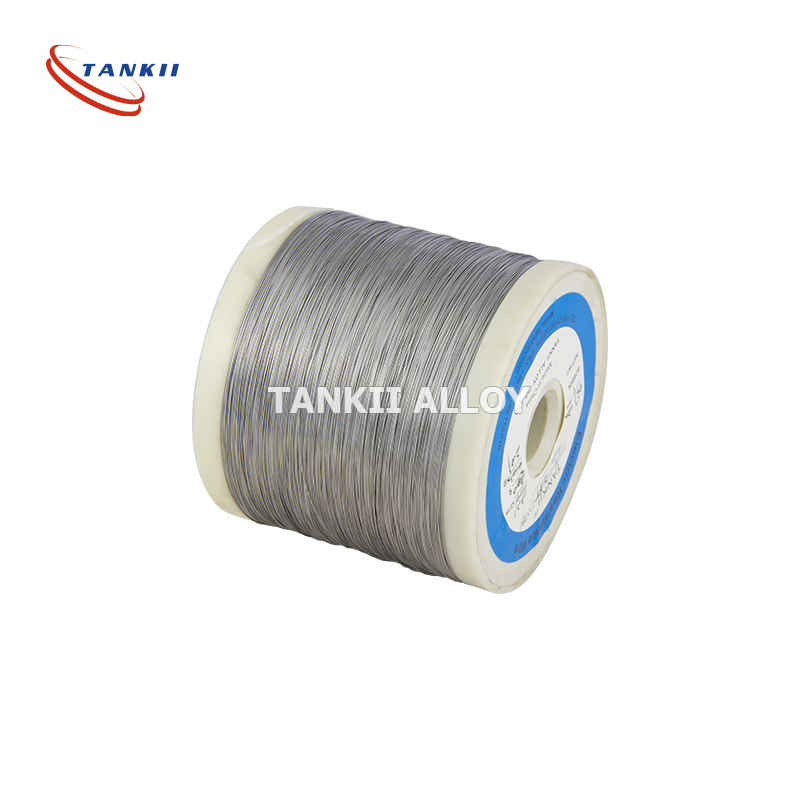

Heat Resistant Electric Wire SWG 20-32 Soft Annealing Bright FeCrAl CrAl134 FeCrAl125 Fecral Resistance Heating Wire

Heat Resistant Electric Wire SWG 20-32 Soft Annealing Bright FeCrAl 1Cr13Al4 Fecral Resistance Heating Wire

Features:

- Fecral electrictrical resistance heating alloys with high electrical resistivity, temperature coefficient of resistance is small. – Good corrosion resistance under high temperature, and particularly suitable for use in a gas containing sulfur and sulfides, low price. – Electric resistance heating wire is one kind of normal material of fecral alloy.

Applications:

- It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive,

military and other industries producing heating elements and resistance elements.

military and other industries producing heating elements and resistance elements.

SIze Dimension Range:

- Wire: 0.01-10 mm

- Ribbon: 0.05*0.2-2.0*6.0 mm

- Strip: 0.05*5.0-5.0*250 mm

- Bar:10-50 mm

- Ribbon: 0.05*0.2-2.0*6.0 mm

- Strip: 0.05*5.0-5.0*250 mm

- Bar:10-50 mm

|

Alloy Type / Performance

|

0Cr25Al5

|

0Cr21Al6

|

0Cr23Al5

|

0Cr21Al4

|

0Cr21Al6Nb

|

0Cr27Al7Mo2

|

||

|

Composition |

Cr

|

12.0-15.0

|

23.0-26.0

|

19.0-22.0

|

20.5-23.5

|

18.0-21.0

|

21.0-23.0

|

26.5-27.8

|

|

Al

|

4.0-6.0

|

4.5-6.5

|

5.0-7.0

|

4.2-5.3

|

3.0-4.2

|

5.0-7.0

|

6.0-7.0

|

|

|

Re

|

Opportune

|

|||||||

|

Fe

|

Rest

|

|||||||

|

Nb0.5

|

Mo1.8-2.2

|

|||||||

|

Max. continuous service temp. of element(℃)

|

950

|

1250

|

1250

|

1250

|

1100

|

1350

|

1400

|

|

|

Resistivity at 20℃(μm.m)

|

1.25

|

1.42

|

1.42

|

1.35

|

1.23

|

1.45

|

1.53

|

|

|

Density(g/cm3)

|

7.4

|

7.1

|

7.16

|

7.25

|

7.35

|

7.1

|

7.1

|

|

|

Thermal conductivity(KJ/m.h.℃)

|

52.7

|

46.1

|

63.2

|

60.2

|

46.9

|

46.1

|

–

|

|

|

Coefficient of lines expansion(ax10-6/℃)

|

15.4

|

16

|

14.7

|

15

|

13.5

|

16

|

16

|

|

|

Melting point approx.(℃)

|

1450

|

1500

|

1500

|

1500

|

1500

|

1510

|

1520

|

|

|

Hardness(H.B.)

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

|

|

Elongation at rupture(%)

|

>16

|

>12

|

>12

|

>12

|

>12

|

>12

|

>10

|

|

|

Repeat Bending frequency(F/R)

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

|

|

Continuous servicetime(Hours/℃)

|

–

|

≥80/1300

|

≥80/1300

|

≥80/1300

|

≥80/1250

|

≥80/1350

|

≥80/1350

|

|

|

Tensile strength(N/mm2)

|

580-680

|

630-780

|

630-780

|

630-780

|

600-700

|

650-800

|

650-800

|

|

|

Variation of area(%)

|

65-75

|

60-75

|

60-75

|

60-75

|

60-75

|

60-75

|

60-75

|

|

|

Micrographic Structure

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

|

|

Magnetic Properties

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

|

Write your message here and send it to us