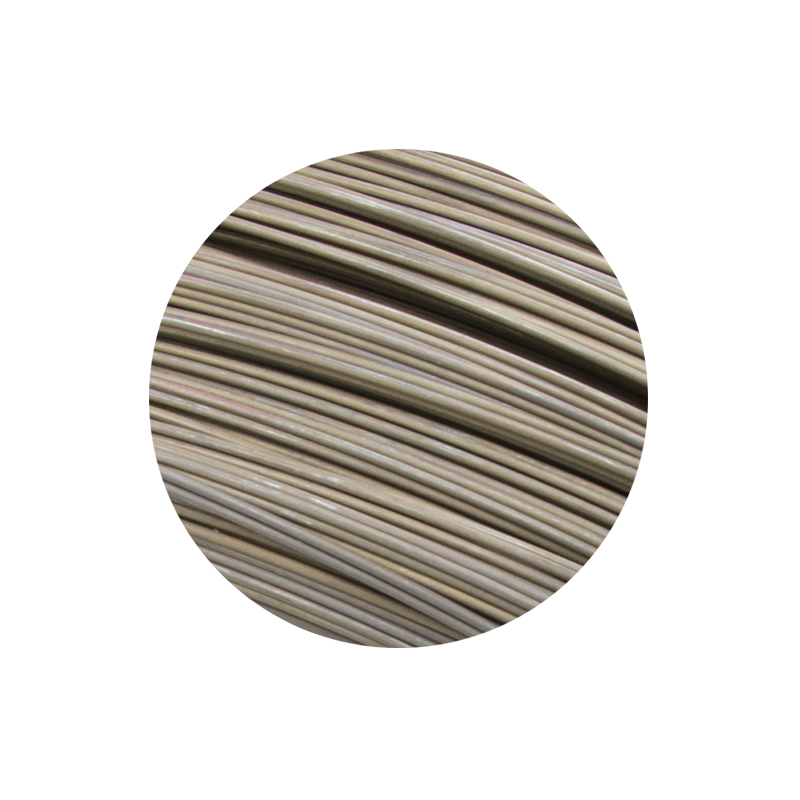

Heating Wire/Heating Furnace coil/Wire FeCR21AL4/FeCr23Al5/ FeCr25Al5/FeCr24AL6Re/ FeCr27Al7Mo2 1.0-10.0mm

Resistance Wire made of Nickel Chrome Alloys, Nickel Chrome Iron Alloys, Iron Chrome Aluminium Alloys, Copper Nickel Alloys.

Mainly used in heater, heating element and resistor, etc.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5,FeCrAl 25-5, etc…

Constantan, Alloy 30, Alloy 60, Alloy 90, etc.

Electric Resistivity from 0.02 u ohm/m-1.53 u ohm/m

Operate Temperature from 200 C to 1400 C

Pls be free to contact us if there is any question.

NiCr:

RESISTOHM 20, RESISTOHM 30, RESISTOHM 40, RESISTOHM 60, RESISTOHM 70, RESISTOHM 80

FeCrAl:

RESISTOHM 125, RESISTOHM 135, RESISTOHM 140,

RESISTOHM 145, RESISTOHM 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| FeCrAl Alloy Grade | Chemical Composition % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Others |

| max(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Bal. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Bal. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Bal. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Bal. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Bal. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Bal. |

Chemical Composition and Propertes:

| Propertes/Grade | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Main Chemical Composition(%) |

Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Max Working Temperature(ºC) |

1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivity at 20ºC (μ Ω · m) |

1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Density(g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Thermal Conductivity

(KJ/m· h· ºC) |

60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of Thermal Expansion(α × 10-6/ºC) |

18 | 17 | 17 | 19 | 19 | |

| Melting Point(ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation(%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Micrographic Structure | austenite | austenite | austenite | austenite | austenite | |

| Magnetic Property | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | |

| CuNi Alloys Grade | Electrical resistivity (20degreeΩ mm² /m) |

temperature coefficient of resistance (10^6/degree) |

Density g/mm² |

Max. temperature (degree) |

Melting point (degree) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |