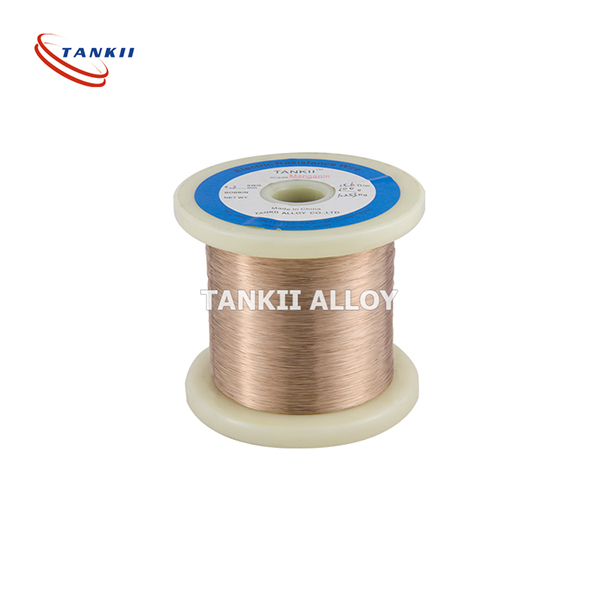

High-Quality 6J12 Wire for Precision Applications

6J12 Alloy Production Description

Overview: 6J12 is a high-precision iron-nickel alloy known for its excellent stability and high precision performance. It is widely used in the manufacturing of temperature compensation components, precision resistors, and other high-precision devices.

Chemical Composition:

Nickel (Ni): 36%

Iron (Fe): 64%

Trace elements: Carbon ©, Silicon (Si), Manganese (Mn)

Physical Properties:

Density: 8.1 g/cm³

Electrical Resistivity: 1.2 μΩ·m

Thermal Expansion Coefficient: 10.5×10⁻⁶/°C (20°C to 500°C)

Specific Heat Capacity: 420 J/(kg·K)

Thermal Conductivity: 13 W/(m·K)

Mechanical Properties:

Tensile Strength: 600 MPa

Elongation: 20%

Hardness: 160 HB

Applications:

Precision Resistors: Due to its low resistivity and high temperature stability, 6J12 is ideal for manufacturing precision resistors, ensuring stable circuit performance under various temperature conditions.

Temperature Compensation Components: The thermal expansion coefficient makes 6J12 an ideal material for temperature compensation components, effectively counteracting dimensional changes due to temperature variations.

Precision Mechanical Parts: With excellent mechanical strength and wear resistance, 6J12 is widely used in the manufacturing of precision mechanical parts, especially those requiring high precision and long service life.

Conclusion: 6J12 alloy is a versatile material with a wide range of applications in precision manufacturing. Its excellent mechanical properties, electrical stability, and performance in high-temperature environments make it an invaluable material in various industries12.