Hot-selling Annealing - Single Spiral 1800°F Bayonet PTFE Bottom Heaters – TANKII

Hot-selling Annealing - Single Spiral 1800°F Bayonet PTFE Bottom Heaters – TANKII Detail:

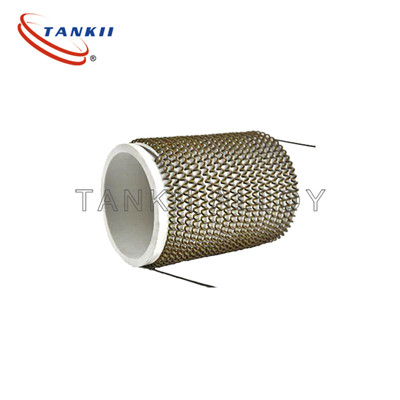

The product is ued in controllable aural various heat treatment furnace, to avoid the contact of elding burning outcome or to avoid the corrosion of furnace gas to heating element. The process(the conversion of elding burning or electric energy) is put into refractory steel tube and let amount of heat radiate by wall of tube. This device is called as heater tube.

Electrothermal heater tube will close the heating element in the jacket, after electrify and heat up, the heat is indirectly radiated to furnace liner and workpiece to be heated by bushing. The heat up of heater tube is used in furnace with going protecting aural and corrodent aural, such as continuous furnace, roller furnace, pit furnace.

The advantages of tube:

The controllability of aural inside furnace can be guaranteed.

The control of temperature, assemble and maintainace are very convenient and can be easy to sealed.

The cubage of hearth is enlarged and throughput is improved because of no muffle pot

Strong heating ability and high efficiency

The refractory steel material is save.

The material of tube:

The electrothermal alloy material that heating tube apply should be of higher resistance rate. The percent conversion of galvanothermy is high. Because the heating tube is put in the bushing, the process of heat transmission is different from that of open type heating element. Its heat shield is big. The temperature of element must be controlled at the course of temperature rise, to avoid temperature excursion of element.

When the heater tube is closed and heated, the surface temperature of heating element is higher roughly than temperature of hearth by 100 C~150 C. So temperature of furnace and atmosphere of temperature of furnace are needed to analysed. Choose correct heating material.

The heater tube produced by gongtao company often apply Cr20Ni80, Cr25A15, Cr21A16Nb, Cr27A17Mo2 ect.

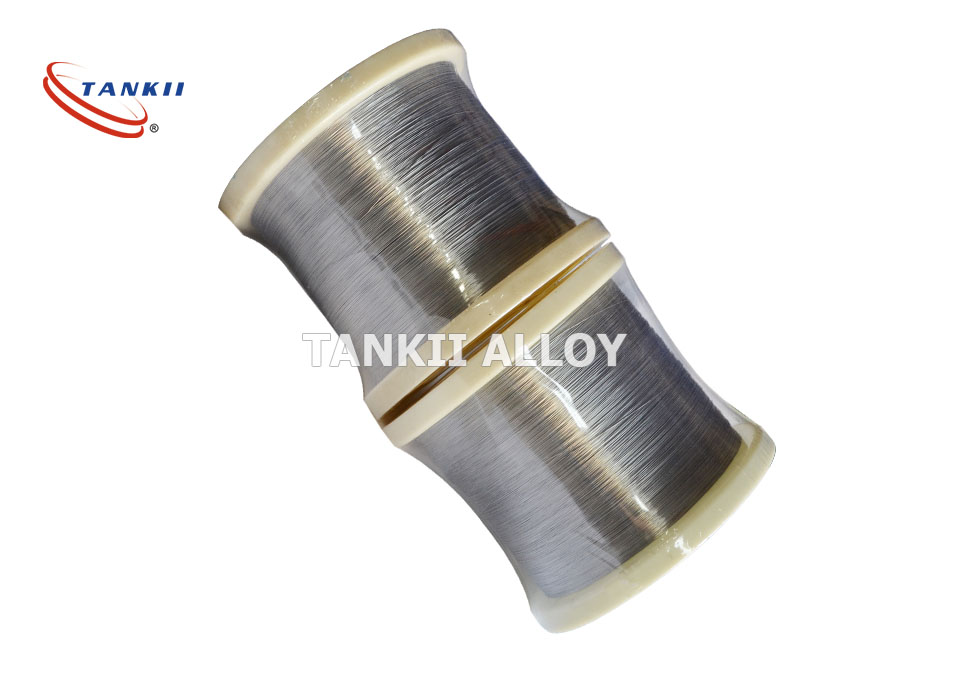

Shanghai Tankii Alloy Material Co., Ltd. Focus on the production of resistance alloy(nichrome Alloy, FeCrAl Alloy, copper nickel alloy, thermocouple wire, precision alloy and thermal spray alloy in the form of wire, sheet, tape, strip, rod and plate. We’ve already got ISO9001 quality system certificate and approval of ISO14001 environmental protection system. We own a complete set of advanced production flow of refining, cold reduction, drawing and heat treating etc. We also proudly have independent R&D capacity.

Shanghai Tankii Alloy Material Co., Ltd has accumulated lots of experiences over 35 years in this field. During these years, more than 60 management elites and high science and technology talents were employed. They participated in every walk of the company life, which make our company keep blooming and invincible in the competitive market. Based on the principle of “first quality, sincere service”, our managing ideology is pursuing technology innovation and creating the top brand in the alloy field. We persist in Quality – the foundation of the survival. It is our forever ideology to serve you with full heart and soul. We committed to provide customers all over the world with high-quality, competitive products and perfect service.

Our products, such us nichrome alloy, precision alloy, thermocouple wire, fecral alloy, copper nickel alloy, thermal spray alloy have been exported to over 60 countries in the world. We are willing to establish strong and long-time partnership with our customers. Most complete range of products dedicated to Resistance, Thermocouple and Furnace manufacturers Quality with end to end production control Technical support and Customer Service.

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for Hot-selling Annealing - Single Spiral 1800°F Bayonet PTFE Bottom Heaters – TANKII , The product will supply to all over the world, such as: Monaco, Denmark, Hungary, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.