Low MOQ for 800 Alloy - Copper Nickel CuNi30 Heating Resistance Wire Alloy Wire – TANKII

Low MOQ for 800 Alloy - Copper Nickel CuNi30 Heating Resistance Wire Alloy Wire – TANKII Detail:

As a big manufacturer and exporter in China on the line of electric resistance alloy, we can supply all kinds of electric resistance alloy wire and strips (resistance steel wire and strips),

Material: CuNi1, CuNi2, CuNi6, CuNi8, CuNi14, CuNi19, CuNi23, CuNi30, CuNi34, CuNi44

General Description

Due to has high tensile strength and increased resistivity values, copper nickel alloy wires are the first choice for applications as resistance wires. With the different nickel amount in this product range, the characteristics of the wire can be chosen according to your requirements. Copper nickel alloy wires are available as bare wire, or enamelled wire with any insulation and self-bonding enamel. Furthermore, litz wire made of enamelled copper nickel alloy wire are available.

Features

1. Higher resistance than copper

2. High tensile strength

3. Good bending proof performance

Application

1. Heating applications

2. Resistance wire

3. Applications with high mechanical requirements

4. Others

Application:

Low-voltage circuit breaker, thermal overload relay, electrical heating cable, electrical heating mats, snow melting cable and mats, ceiling radiant heating mats, Floor heating mats & Cables, Freeze protection cables, electrical heat tracers, PTFE heating cables, hose heaters, and other low-voltage electrical product

Main grades and properties

| Type | Electrical resistivity (20degreeΩ mm²/m) |

temperature coefficient of resistance (10^6/degree) |

Dens ity g/mm² |

Max. temperature (°c) |

Melting point (°c) |

| CuNi1 | 0.03 | <1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | <1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | <600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | <570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | <500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | <380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | <250 | 8.9 | 300 | 1135 |

| CuNi23 | 0.30 | <160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | <100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ±40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.49 | <-6 | 8.9 | 400 | 1280 |

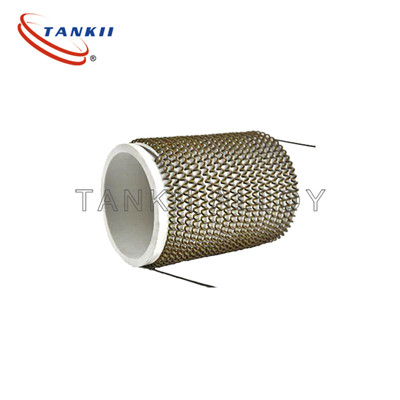

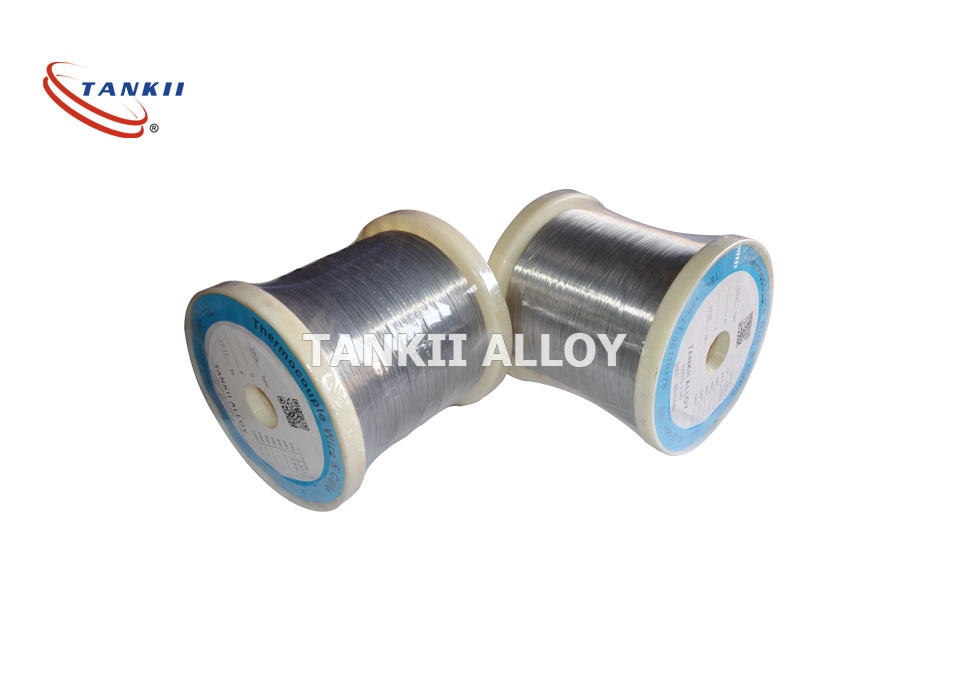

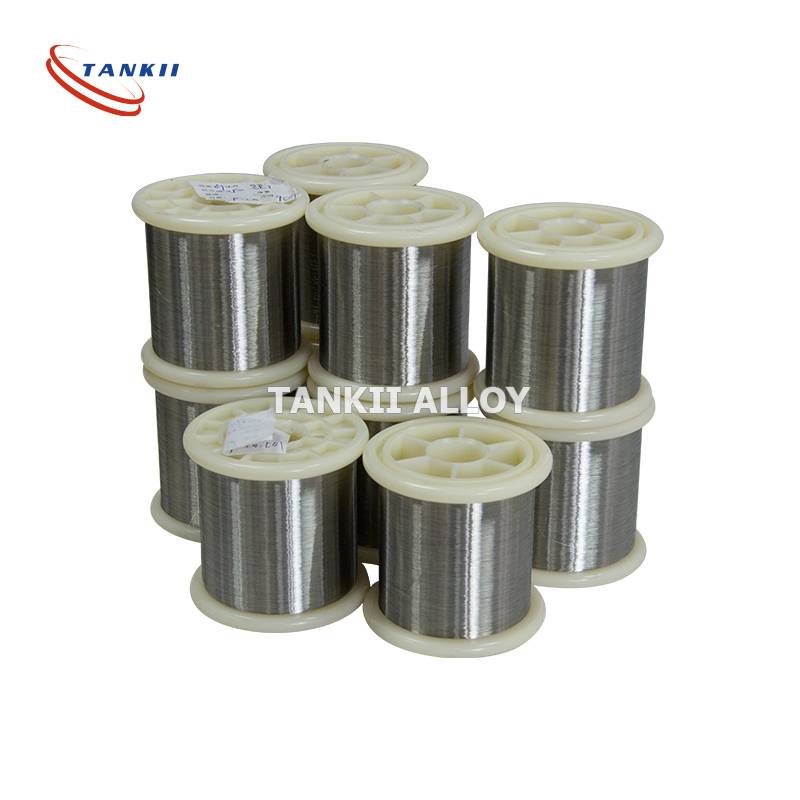

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Low MOQ for 800 Alloy - Copper Nickel CuNi30 Heating Resistance Wire Alloy Wire – TANKII , The product will supply to all over the world, such as: venezuela, Florence, belarus, With high quality, reasonable price, on-time delivery and customized & customized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!