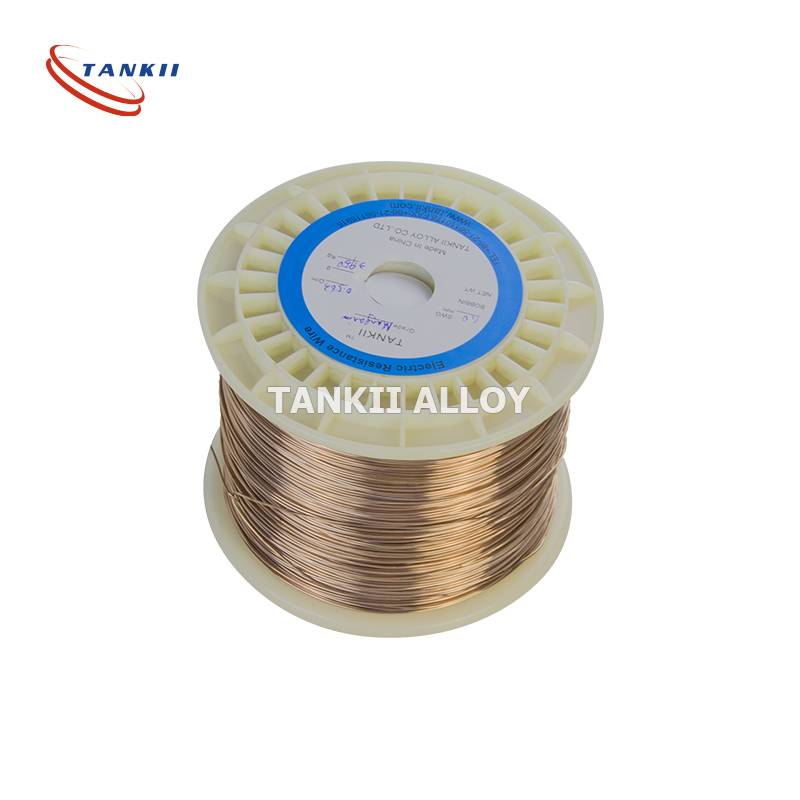

Manganin 130 Mn-Cu wire manganin resistance wire for resistor

Manganin is a trademarked name for an alloy of typically 86% copper, 12% manganese, and 2% nickel. It was first developed by Edward Weston in 1892, improving upon his Constantan (1887).

A resistance alloy with moderate resistivity and low temperature coefficent. The resistance/temperature curve is not as flat as the constantans nor are the corrosion resistance properties as good.

Manganin foil and wire is used in the manufacture of resistors, particularly ammeter shunts, because of its virtually zero temperature coefficient of resistance value[1] and long term stability. Several Manganin resistors served as the legal standard for the ohm in the United States from 1901 to 1990.[2] Manganin wire is also used as an electrical conductor in cryogenic systems, minimizing heat transfer between points which need electrical connections.

Manganin is also used in gauges for studies of high-pressure shock waves (such as those generated from the detonation of explosives) because it has low strain sensitivity but high hydrostatic pressure sensitivity.

Resistance of Wires – 20 deg C Manganin Q = 44. x 10-6 ohm cm Gage B&S / ohms per cm / ohms per ft 10 .000836 .0255 12 .00133 .0405 14 .00211 .0644 16 .00336 .102 18 .00535 .163 20 .00850 .259 22 .0135 .412 24 .0215 .655 26 .0342 1.04 27 .0431 1.31 28 .0543 1.66 30 .0864 2.63 32 .137 4.19 34 .218 6.66 36 .347 10.6 40 .878 26.8 Manganin Alloy CAS Number: CAS# 12606-19-8

Synonyms

Manganin, Manganin Alloy, Manganin shunt, Manganin strip, Manganin wire, Nickel plated copper wire, CuMn12Ni, CuMn4Ni, Manganin copper alloy, HAI, ASTM B 267 Class 6, Class 12, Class 13. Class 43,