Welcome to our websites!

Manufacturer for Mechanical Components - Nickel 212/UNS N02212 Nickel-Manganese Alloys As Fuses – TANKII

Manufacturer for Mechanical Components - Nickel 212/UNS N02212 Nickel-Manganese Alloys As Fuses – TANKII Detail:

Nickel 212 is also similar to Nickel 200 with manganese addition to improve strength.

Nickel 212 is used as fuses for lead-in-wire components in light bulbs. It is also used as lead wires for electrical components and as supporting components in electronic valves and cathode ray tubes. It is also finds use as electrodes in glow discharge lamps.

Chemical Composition

|

Element |

Min % |

Max % |

|

Ni + Co |

97.0 |

– |

|

Mn |

1.50 |

2.50 |

|

Fe |

– |

0.25 |

|

C |

– |

0.10 |

|

Cu |

– |

0.20 |

|

Si |

– |

0.20 |

|

Mg |

– |

0.20 |

|

S |

– |

0.006 |

|

Density |

Melting Point |

Coefficient of Expansion |

Modulus of Rigidity |

Modulus of Elasticity |

| 8.86 g/cm³ | 1446 °C | 12.9 μm/m °C (20 – 100 °C) | 78 kN/mm² | 196 kN/mm² |

| 0.320 lb/in³ | 2635 °F | 7.2 x 10-6 in/in °F (70 – 212 °F) | 11313 ksi | 28400 ksi |

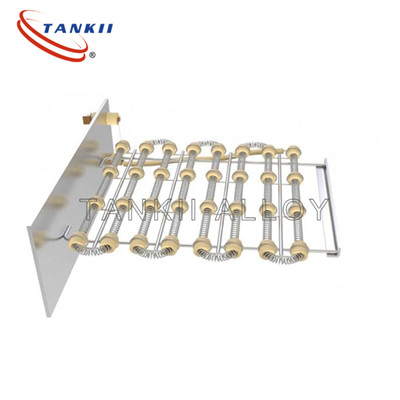

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Manufacturer for Mechanical Components - Nickel 212/UNS N02212 Nickel-Manganese Alloys As Fuses – TANKII , The product will supply to all over the world, such as: Hungary, UK, Singapore, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Write your message here and send it to us