Manufacturer of Laboratory Furnaces - Alkrothal 720 No.1 JR FeCrAl Alloy for brake resistor – TANKII

Manufacturer of Laboratory Furnaces - Alkrothal 720 No.1 JR FeCrAl Alloy for brake resistor – TANKII Detail:

Alkrothal 720 No.1 JR for brake resistor

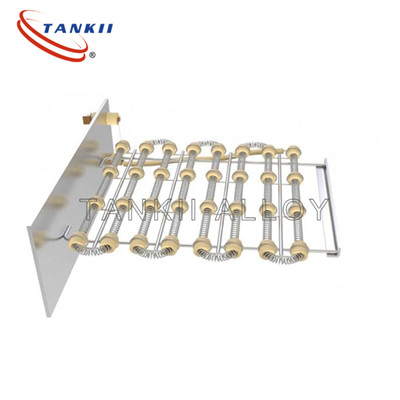

Typical applications for Alkrothal 720 are in rheostats, braking resistors, etc. It is also used as electrical heating elements in industrial applications.

Alkrothal 720 is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to 1000°C (1830°F).

Nominal Analysis

| Cr | Al | Fe |

| 12.0~15.0 | 4.0~6.0 | Balance |

Mechanical Properties

| Max Continuous Service Temperature: Resisivity 20ºC: Density: Thermal Conductivity: Coefficient of Thermal Expansion: Melting Point: Elongation: Micrographic Structure: Magnetic Property: |

950ºC 1.25ohm mm2/m 7.40g/cm3 52.7 KJ/m·h·ºC 15.4×10-6/ºC (20ºC~1000ºC) 1450ºC Min 16% Ferrite magnetic |

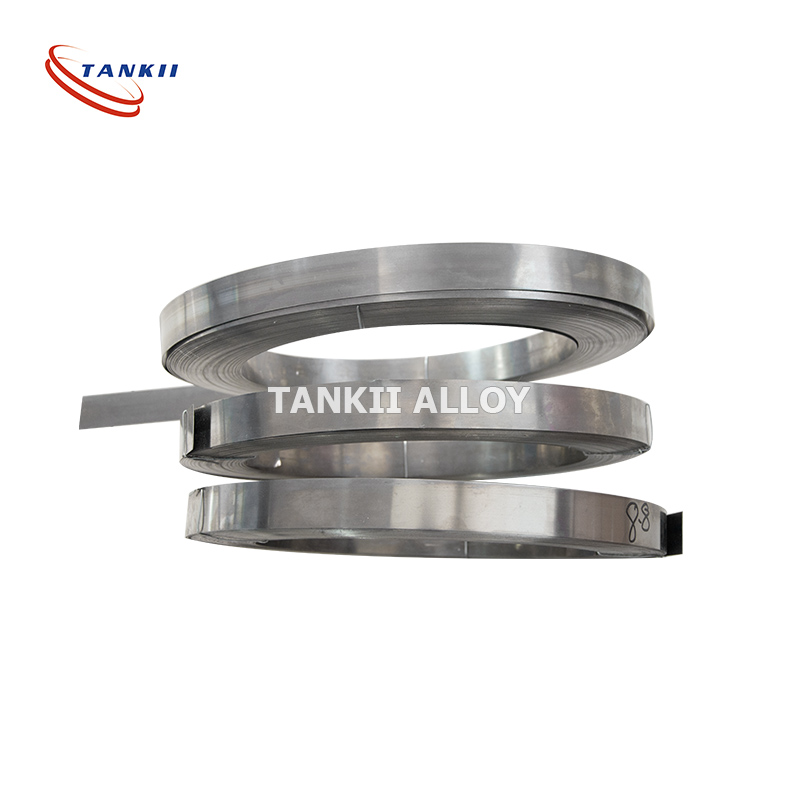

Size: Thickness 0.01-7mm, width 0.5-1000mm

Surface: BA, 2B

Hardness: Soft, Half hard, hard

Has been used extensively as big power brake resisor and furnace heating elements.

Has less hot strength than Tophet alloys but much higher melting point.

Shanghai TANKII ALLOY MATERIAL Co., Ltd.

FECRAL AND ALCHROME ALLOY PRODUCER IN China, MOST PROFESSIONAL IN THE WORLD

We also produce below grades:

0Cr15Al5 and 0Cr19Al3, etc.

| Chemical Composition and Main Property of Fe-Cr-Al Resistance Alloy | ||||||||

| Properties Grade | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main Chemical Composition (%) |

Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max Continuous Service Temperature(oC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resisivity 20oC (Ωmm2/m) | 1.25 ±0.08 |

1.42 ±0.06 |

1.42 ±0.07 |

1.35 ±0.07 |

1.23 ±0.07 |

1.45 ±0.07 |

1.53 ±0.07 |

|

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal Conductivity | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| (KJ/m@h@oC) | ||||||||

| Coefficient of Thermal Expansion(α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Approximate Melting Point( oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile Strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Section Variation | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Shrink Rate (%) | ||||||||

| Repeatedly Bend Frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Continuous Service Time | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic Structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic Property | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Manufacturer of Laboratory Furnaces - Alkrothal 720 No.1 JR FeCrAl Alloy for brake resistor – TANKII , The product will supply to all over the world, such as: Jersey, Nicaragua, Washington, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.