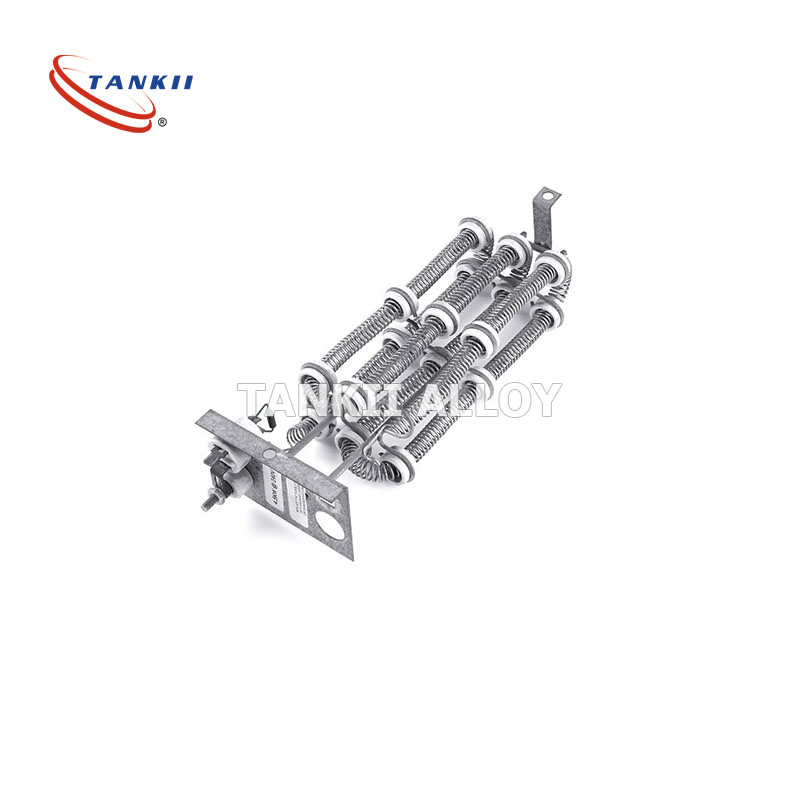

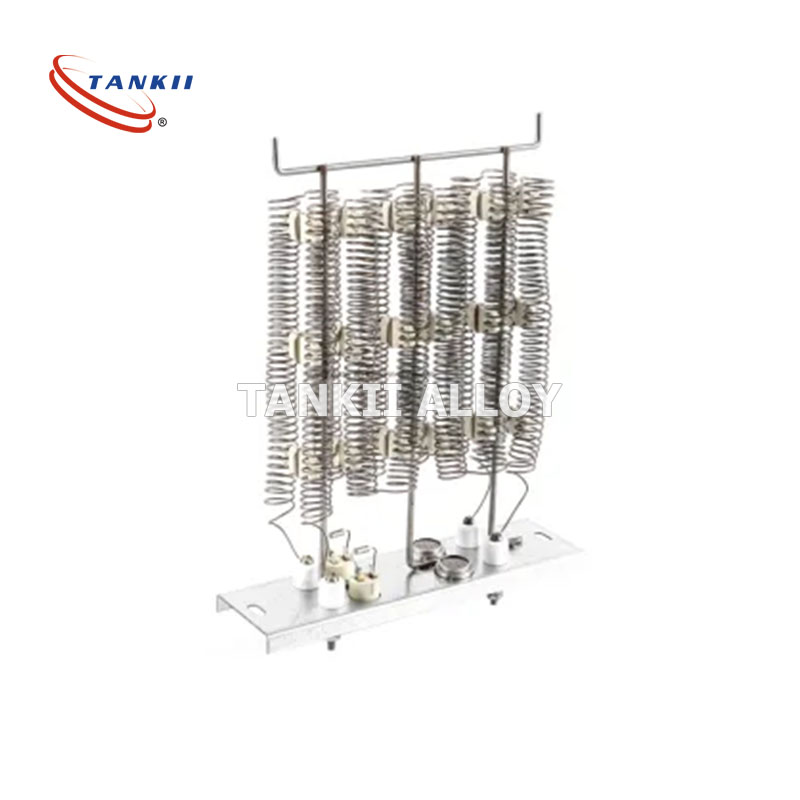

Multi Strand Coils Open Coil Air Duct Heaters High Velocity Hand Dryer

Open coil elements are the most efficient type of electric heating element while also the most economically feasible for most heating applications. Used predominantly in the duct heating industry, open coil elements have open circuits that heat air directly from the suspended resistive coils. These industrial heating elements have fast heat up times that improve efficiency and have been designed for low maintenance and easily, inexpensive replacement parts.

Recommendations

For applications in a humid environment, we recommend the optional NiCr 80 (grade A) elements.

They are composed of 80% Nickel and 20% Chrome (does not contain iron).

This will allow a maximum operating temperature of 2,100o F (1,150o C) and installation where condensation may be present in the air duct.

Open coil elements are the most efficient type of electric heating element while also the most economically feasible for most heating applications. Used predominantly in the duct heating industry, open coil elements have open circuits that heat air directly from the suspended resistive coils. These industrial heating elements have fast heat up times that improve efficiency and have been designed for low maintenance and easily, inexpensive replacement parts.

Open coil heating elements are typically made for duct process heating, forced air & ovens and for pipe heating applications. Open coil heaters are used in tank and pipe heating and/or metal tubing. A minimum clearance of 1/8’’ is required between the ceramic and the inside wall of the tube. Installing an open coil element will provide excellent and uniform heat distribution over a large surface area.

Open coil heater elements are an indirect industrial heating solution to decrease watt density requirements or the heat fluxes on the surface area of the pipe connected to the heated section and prevent heat sensitive materials from coking or breaking down.