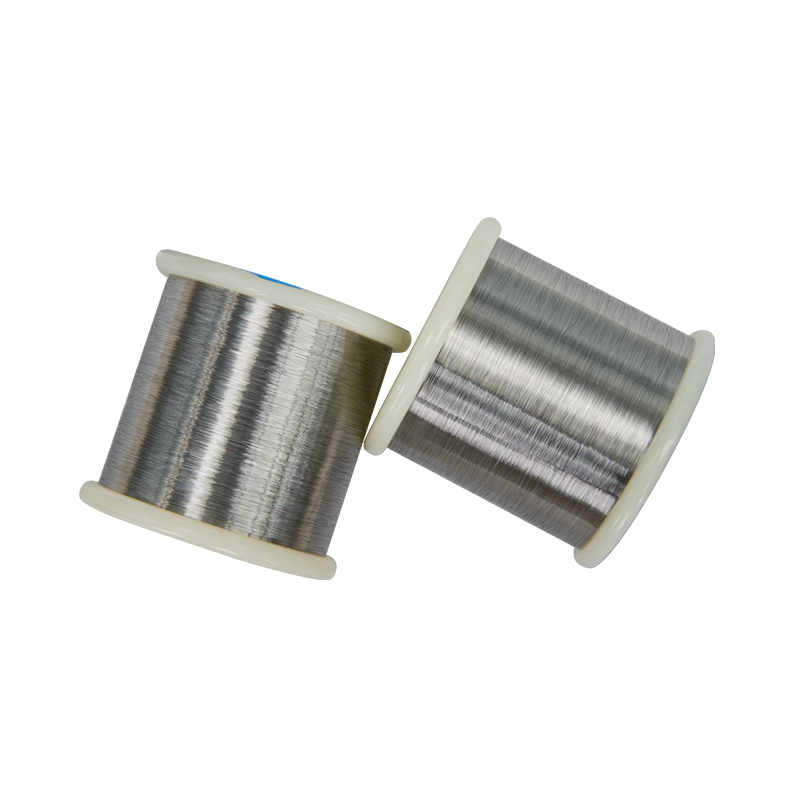

Nife 52 / ASTM F30 / Nilo 52 / 52h / N52 Fe-Ni Constant Expansion Alloy Wire

Alloy 52 Contains 52% nickel and 48% iron and is widely used in the telecommunications industry.It also finds a application in a wide variety of electronic applications,especially for glass seals.

Alloy 52 is one of the glass to metal sealing alloys designed for use with a variety of soft glasses. Known for a coefficient of thermal expansion that is almost constant up to 1050F (565 C).

Size Range:

*Sheet —Thickness 0.1mm~40.0mm, width:≤300mm,Condition: cold rolled(hot), bright, bright annealed

*Round Wire—Dia 0.1mm~Dia 5.0mm,Condition: cold drawn, bright, bright annealed

*Flat Wire —Dia 0.5mm~Dia 5.0mm,length:≤1000mm,Condition:flat rolled, bright annealed

*Bar —Dia 5.0mm~Dia 8.0mm,length:≤2000mm,Condition:cold drawn,bright, bright annealed

Dia 8.0mm~Dia 32.0mm,length:≤2500mm,Condition:hot rolled,bright, bright annealed

Dia 32.0mm~Dia 180.0mm,length:≤1300mm,Condition:hot forging,peeled, turned, hot treated

*Capillary —OD 8.0mm~1.0mm,ID 0.1mm~8.0mm,length:≤2500mm,Condition: cold drawn, bright, bright annealed.

*Pipe —OD 120mm~8.0mm,ID 8.0mm~129mm,length:≤4000mm,Condition: cold drawn, bright, bright annealed.

Chemistry:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Min | – | – | – | – | – | – | – | – | 50.5 | – |

| Max | 0.25 | 0.10 | 0.05 | Bal. | 0.60 | 0.30 | 0.025 | 0.025 | – | 0.5 |

Average Linear Expansion Coefficient:

| Grade | α1/10-6ºC-1 | |||||||

| 20~100ºC | 20~200ºC | 20~300ºC | 20~350ºC | 20~400ºC | 20~450ºC | 20~500ºC | 20~600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Properties:

| Condition | Approx. tensile strength | Approx. operating temperature | ||

| N/mm² | ksi | °C | °F | |

| Annealed | 450 – 550 | 65 – 80 | up to +450 | up to +840 |

| Hard Drawn | 700 – 900 | 102 – 131 | up to +450 | up to +840 |

| Forming: |

| The alloy has good ductility and can be formed by standard means. |

| Welding: |

| Welding by conventional methods is appropriate for this alloy. |

| Heat Treatment: |

| Alloy 52 should be annealed at 1500F followed by air cooling. Intermediate strain relieving can be performed at 1000F. |

| Forging: |

| Forging should be done at a temperature of 2150 F. |

| Cold Working: |

| The alloy is readily cold worked. Deep drawing grade should be specified for that forming operation and annealed grade for general forming. |