Welcome to our websites!

OEM China Alloy 52 - CuNi Resistance Wire CuNi8 Alloy Wire – TANKII

OEM China Alloy 52 - CuNi Resistance Wire CuNi8 Alloy Wire – TANKII Detail:

Copper nickel alloy, which has low electric resistance, good heat-resistant and corrosion-resistant, easy to be processed and lead welded. It is used to make the key components in the thermal overload relay, low resistance thermal circuit breaker, and the electrical appliances. It is also an important material for electrical heating cable.

Main grades and properties

| Type | Electrical resistivity (20degreeΩ mm²/m) |

temperature coefficient of resistance (10^6/degree) |

Dens ity g/mm² |

Max. temperature (°c) |

Melting point (°c) |

| CuNi1 | 0.03 | <1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | <1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | <600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | <570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | <500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | <380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | <250 | 8.9 | 300 | 1135 |

| CuNi23 | 0.30 | <160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | <100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ±40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.49 | <-6 | 8.9 | 400 | 1280 |

Application of copper nickel alloy wire:

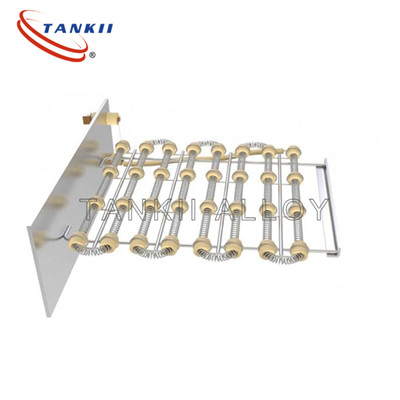

1. heating components

2. current-limiting resistance of thermal overload relay

3. low-voltage circuit breaker

4. low-voltage apparatus

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for OEM China Alloy 52 - CuNi Resistance Wire CuNi8 Alloy Wire – TANKII , The product will supply to all over the world, such as: Angola, Ukraine, Chile, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

Write your message here and send it to us