OEM Factory for Af - Iron Chrome Aluminum Resistance Alloys – TANKII

OEM Factory for Af - Iron Chrome Aluminum Resistance Alloys – TANKII Detail:

Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F).

These Ferritic alloys are known to have higher surface loading capability, higher resistivity and lower density than Nickel Chrome (NiCr) alternatives which can translate to less material in application and weight savings. The higher maximum operating temperatures can also lead to longer element life. Iron Chrome Aluminum alloys form a light grey Aluminum Oxide (Al2O3) at temperatures above 1,000°C (1,832°F) which increases corrosion resistance as well as acts as an electrical insulator. The oxide formation is considered self-insulating and protects against short circuiting in the event of metal to metal contact. Iron Chrome Aluminum alloys have lower mechanical strength when compared to Nickel Chrome materials as well as lower creep strength.

Specification of Cold-drawing Round Type heating wire

|

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

|

0.03-0.05 |

±0.005 |

>0.50-1.00 |

±0.02 |

|

>0.05-0.10 |

±0.006 |

>1.00-3.00 |

±0.03 |

|

>0.10-0.20 |

±0.008 |

>3.00-6.00 |

±0.04 |

|

>0.20-0.30 |

±0.010 |

>6.00-8.00 |

±0.05 |

|

>0.30-0.50 |

±0.015 |

>8.00-12.0 |

±0.4 |

Specification of Cold-drawing Strip Type heating wire

|

Thickness(mm) |

Tolerance(mm) |

Width(mm) |

Tolerance(mm) |

|

0.05-0.10 |

±0.010 |

5.00-10.0 |

±0.2 |

|

>0.10-0.20 |

±0.015 |

>10.0-20.0 |

±0.2 |

|

>0.20-0.50 |

±0.020 |

>20.0-30.0 |

±0.2 |

|

>0.50-1.00 |

±0.030 |

>30.0-50.0 |

±0.3 |

|

>1.00-1.80 |

±0.040 |

>50.0-90.0 |

±0.3 |

|

>1.80-2.50 |

±0.050 |

>90.0-120.0 |

±0.5 |

|

>2.50-3.50 |

±0.060 |

>120.0-250.0 |

±0.6 |

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

1Cr13Al4 |

0.03-12.0 |

1.25±0.08 |

588-735 |

>16 |

>6 |

950 |

>10000 |

|

0Cr15Al5 |

1.25±0.08 |

588-735 |

>16 |

>6 |

1000 |

>10000 |

|

|

0Cr25Al5 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

0Cr23Al5 |

1.35±0.06 |

634-784 |

>12 |

>5 |

1250 |

>8000 |

|

|

0Cr21Al6 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

1Cr20Al3 |

1.23±0.06 |

634-784 |

>12 |

>5 |

1100 |

>8000 |

|

|

0Cr21Al6Nb |

1.45±0.07 |

634-784 |

>12 |

>5 |

1350 |

>8000 |

|

|

0Cr27Al7Mo2 |

0.03-12.0 |

1.53±0.07 |

686-784 |

>12 |

>5 |

1400 |

>8000 |

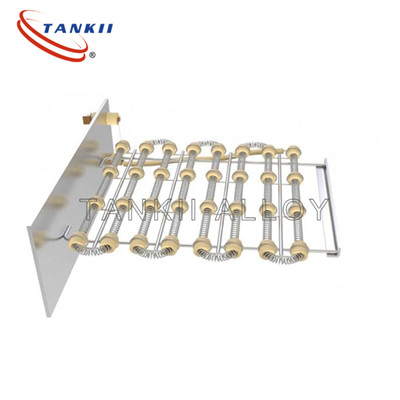

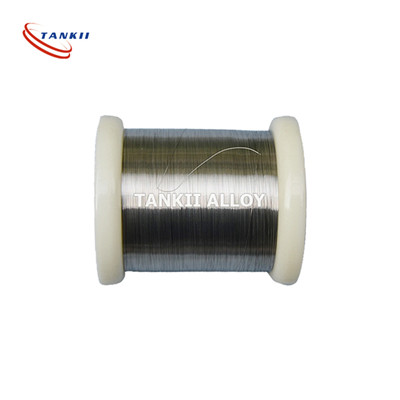

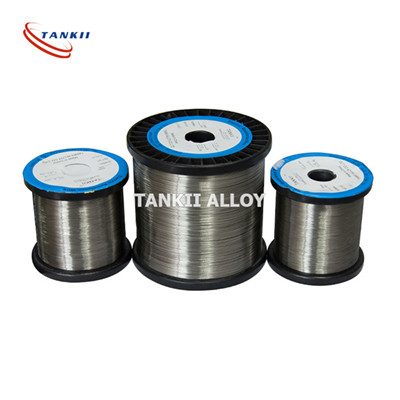

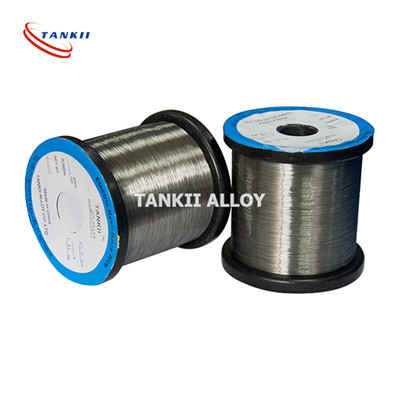

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for OEM Factory for Af - Iron Chrome Aluminum Resistance Alloys – TANKII , The product will supply to all over the world, such as: The Swiss, Indonesia, Malaysia, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We are looking for the wholesale, Drop ship. Please contact us if you are interesting our products. Hope to do business with you all. High quality and fast shipment!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!