OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII

OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII Detail:

Nickel chrome alloy wire Ni70Cr30

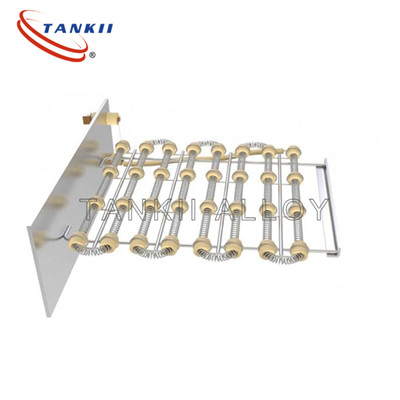

Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip,Sable Resistance For Heating Element,

NiCr70/30

Nickel chromium alloy with iron resistance electrothermal high resistivity, surface body sexual well. At high temperature and high intensity,

and a good performance and processing may welding nature widely used metallurgical, electrical, mechanical components and electrical

manufacturing industries for doing heat resistance material.

NiCr Type:Cr20Ni80,Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 etc.Series electric flat belt, electric fire wire.

3.Product size:

Thickness : 0.02—-4.0mm

Width: 2.5—-250mm

Standard:GB1234-95

Bright and Smooth surface

Ni70Cr30

Chemical Content, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Bal. | Max 0.50 | Max 1.0 | - |

Mechanical Properties

|

Max Continuous Service Temperature: Resisivity ( 20ºC)/Ω·m:: Density: |

1250ºC 1.18 +/-0.05 (Dia: <0.5mm) 1.20+/-0.05 (Dia: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Min 20% Austenite nonmagnetic |

| Type | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Main chemical composition | Ni | Rest | 55.0~61.0 | Rest | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Rest | ≤1 | Rest | Rest | |

| Maximal Temperature(ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Resistance Temperature correction coefficient.(CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Melting point (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivityρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Fast life value | Tem.(ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| hour(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Specific gravity(g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Elongation(%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Thermal(kj/m.h.ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Specific heat(20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Extend strength(20~1000ºC)α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Tensile strength(kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Repeatedly bending(F/R) | >12 | >12 | >12 | >12 | >12 | |

| Microstructure | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII , The product will supply to all over the world, such as: Cairo, Sierra Leone, Barcelona, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!