Parallel Enamelled Copper Wire High Temperature Resistance For Handset

Pure Sterling Silver 925 Enamelled/ Varnished Thread Wire for Motor Coil

Product Description

These enameled resistance wires have been broadly used for standard resistors, automobile

parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating.

Furthermore, we will carry out enamel coating insulation of precious metal wire such as silver and platinum wire upon order. Please make use of this production-on-order.

Type Of Bare Alloy Wire

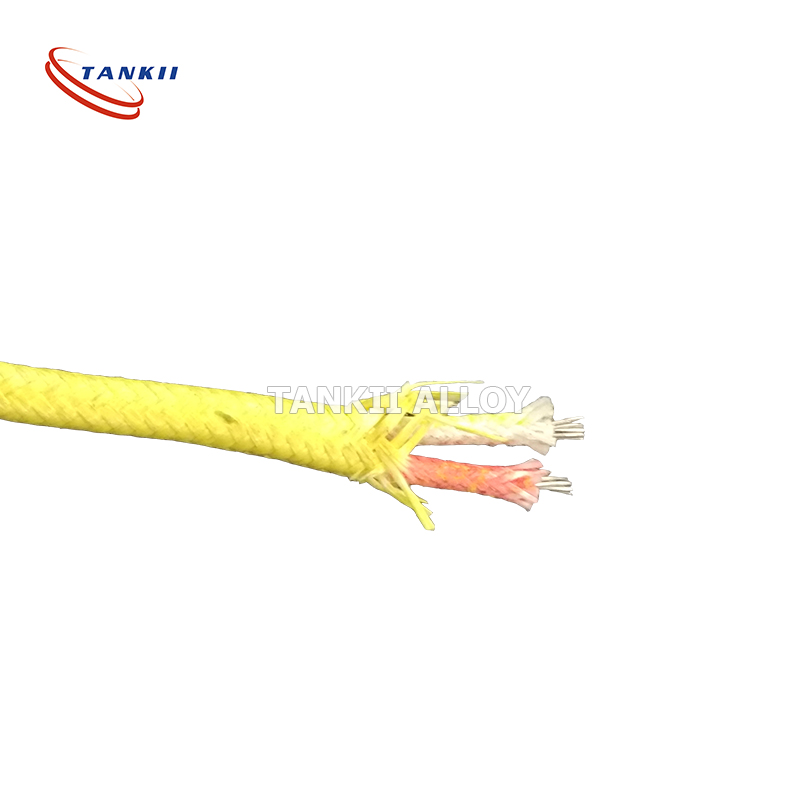

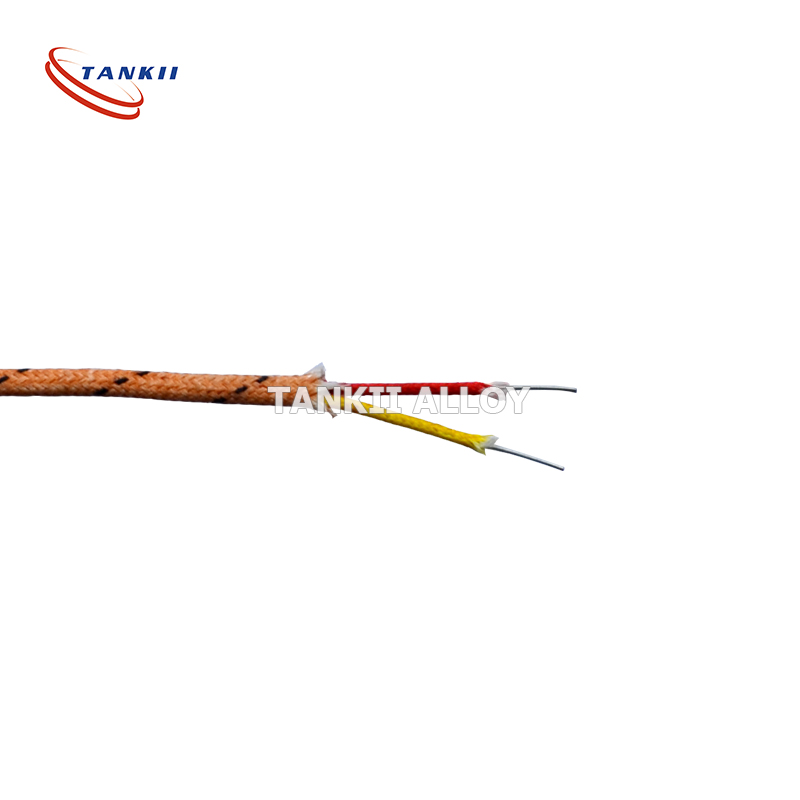

The alloy we can do enamelled are Copper-nickel alloy wire,Constantan wire,Manganin wire. Kama Wire,NiCr Alloy wire,FeCrAl Alloy wire etc alloy wire

Size:

Round wire:0.018mm~2.5mm

Color of enamel insulation:Red,Green,Yellow,Black,Blue,Nature etc.

Ribbon Size:0.01mm*0.2mm~1.2mm*5mm

Moq:5kg each size

| Item | Purity | Molecular formula | Atomic weight | Density | Melting point | Boiling point |

| Parameter | 99.999% / 99.99995% | Cu | 63.55. | 8.96 | 1083.4 | 2567 |

As envelope alternatives of pure enameled copper wire, it has good performance of high frequency transmission, originally it was applied in various types of high-frequency electromagnetic induction coil; now in order to save more production cost, ECCA wire has been widely used in various types of electronic coils, transformers, inductors, rectifiers, and all kinds of large and small motors, and has excellent soldering performance. Its density is low, the weight of the unit product can at least save 40% of the copper wire, it can save a lot of cost of production material.

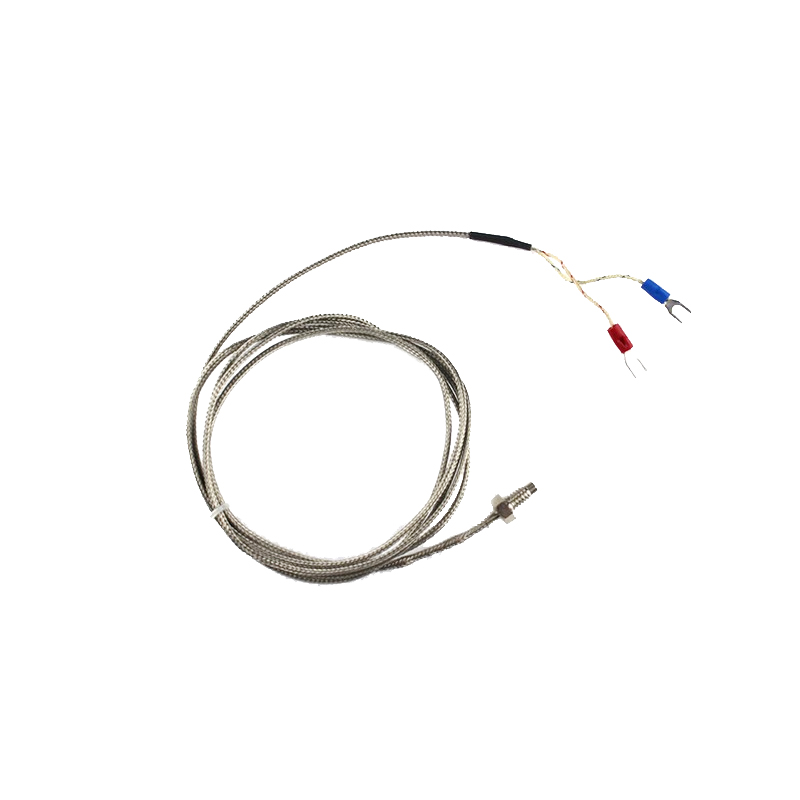

Flexible copper connectors, adopt to various of hihg and low Electric Appliance, Vacuum Electronic Appliance.

Mineral Product Flame-Proof Switch and also cars, Locomotive which used as a connector. The products using bare copper wire or tinned braided copper wire(stranded copper wire), taking the method of cold press.

The interface can be tinned or silvered according to customer’s requires.