T Type Thermocouple Constantan Wire with TP TN for Thermometer

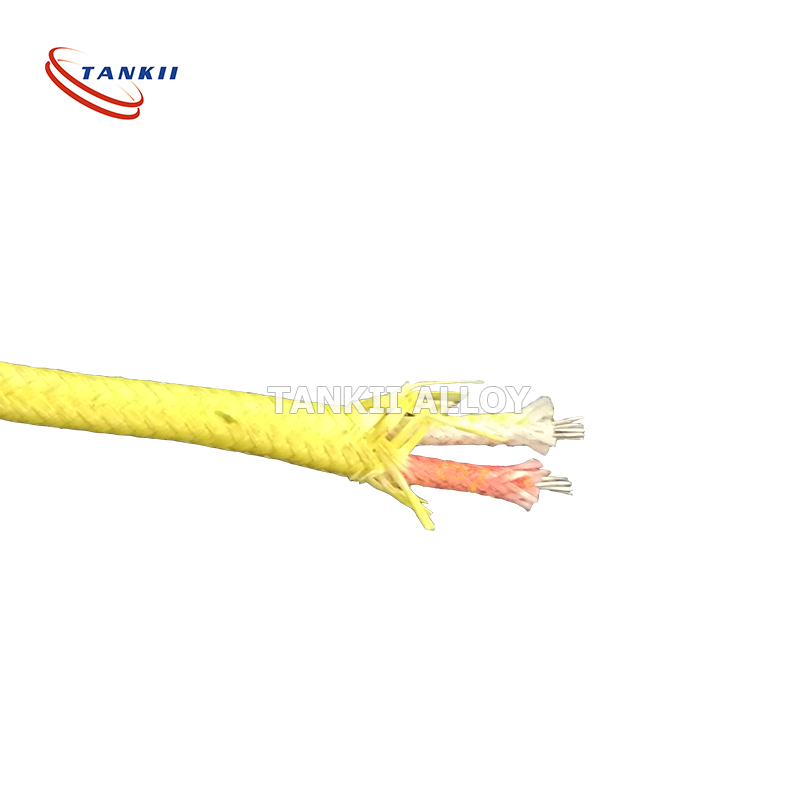

The thermocouple compensation cables can also be termed as instrumentation cables, since they are used for process temperature measurement. The construction is similar to pair instrumentation cable but the conductor material is different. Thermocouples are used in processes to sense temperature and is connected to the pyrometers for indication and control. The thermocouple and pyrometer are electrically conducted by thermocouple extension cables / thermocouple compensating cables. The conductors used for these thermocouple cables are required to have similar thermo-electric (emf) properties as that of the thermocouple used for sensing the temperature.

Type T Thermocouple (Copper + / Constantan – ) T is a narrow range and high accuracy thermocouple wire. It’s popular with scientific and medical temperature monitoring installations . It’s accuracy ±1°C / 2°F for standard limits and ±0.5°C / 1°F for special limits, and has a temperature range -330°F ~ 662°F (-200°C ~ 350°C) depending on wire gauge size.

Our plant mainly manufacture type KX,NX,EX,JX,NC,TX,SC/RC,KCA,KCB compensating wire for thermocouple, and they are used in temperature measurement instruments and cables. Our thermocouple compensating products are all made abiding by GB/T 4990-2010 ‘Alloy wires of extension and compensating cables for thermocouples’ (Chinese National Standard), and also IEC584-3 ‘Thermocouple part 3-compensating wire’ (International standard).

The representing of the comp. wire: thermocouple code+C/X , e.g. SC, KX

X: Short for extension, means that the compensation wire’s alloy is as the same as the the alloy of the thermocouple

C: Short for compensation, means that the compensation wire’s alloy has similar characters with the thermocouple’s alloy in a certain temperature range.

Application:

1. Heating – Gas burners for ovens

2. Cooling – Freezers

3. Engine protection – Temperatures and surface temperatures

4. High temperature control – Iron casting

Detailed Parameters

| Thermocouple Code | Comp. Type | Comp. Wire Name | Positive | Negative | ||

| Name | Code | Name | Code | |||

| S | SC | copper-constantan 0.6 | copper | SPC | constantan 0.6 | SNC |

| R | RC | copper-constantan 0.6 | copper | RPC | constantan 0.6 | RNC |

| K | KCA | Iron-constantan22 | Iron | KPCA | constantan22 | KNCA |

| K | KCB | copper-constantan 40 | copper | KPCB | constantan 40 | KNCB |

| K | KX | Chromel10-NiSi3 | Chromel10 | KPX | NiSi3 | KNX |

| N | NC | Iron-constantan 18 | Iron | NPC | constantan 18 | NNC |

| N | NX | NiCr14Si-NiSi4Mg | NiCr14Si | NPX | NiSi4Mg | NNX |

| E | EX | NiCr10-Constantan45 | NiCr10 | EPX | Constantan45 | ENX |

| J | JX | Iron-constantan 45 | Iron | JPX | constantan 45 | JNX |

| T | TX | copper-constantan 45 | copper | TPX | constantan 45 | TNX |

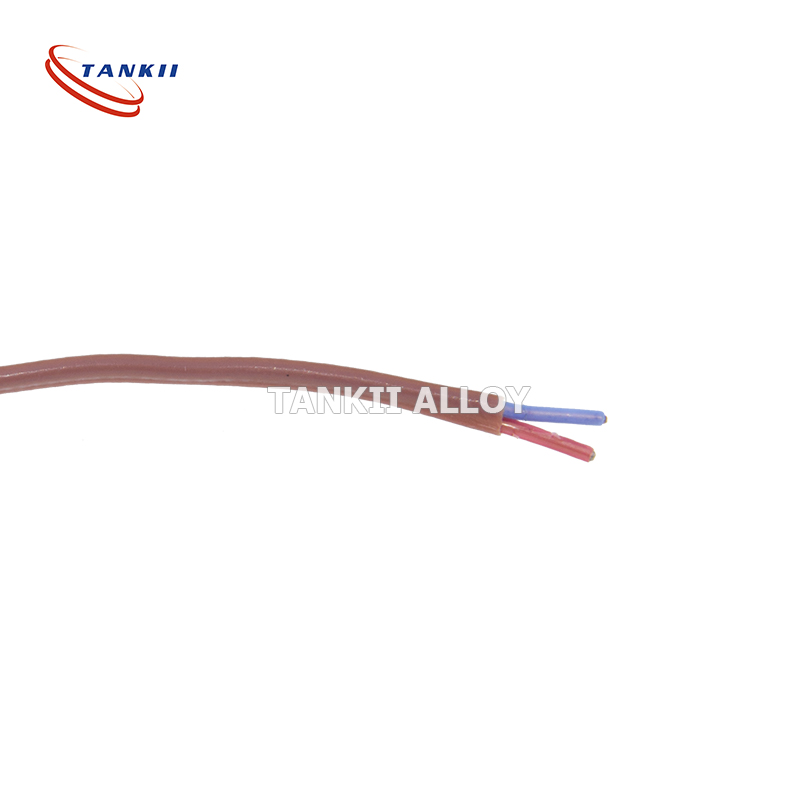

| The color of Insulation and Sheath | ||||||

| Type | Insulation Color | Sheath Color | ||||

| Positive | Negative | G | H | |||

| / | S | / | S | |||

| SC/RC | RED | GREEN | BLACK | GRAY | BLACK | YELLOW |

| KCA | RED | BLUE | BLACK | GRAY | BLACK | YELLOW |

| KCB | RED | BLUE | BLACK | GRAY | BLACK | YELLOW |

| KX | RED | BLACK | BLACK | GRAY | BLACK | YELLOW |

| NC | RED | GRAY | BLACK | GRAY | BLACK | YELLOW |

| NX | RED | GRAY | BLACK | GRAY | BLACK | YELLOW |

| EX | RED | BROWN | BLACK | GRAY | BLACK | YELLOW |

| JX | RED | PURPLE | BLACK | GRAY | BLACK | YELLOW |

| TX | RED | WHITE | BLACK | GRAY | BLACK | YELLOW |

| Note: G–For general use H–For heat resistant use S–Precision class Normal class has no sign | ||||||

Packaging Details: 500m/1000m per roll with plastic film wrapped and carton package. As the order quantity and customer requirement.

Delivery Detail: By sea/ air/Express delivery