Welcome to our websites!

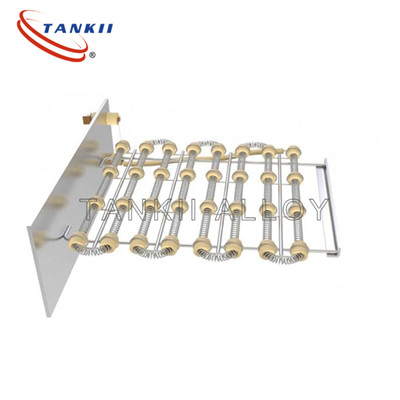

Wholesale Dealers of Diffusion Furnaces - FeCrAl ocr23al5 high resistance heating strip element for furnace – TANKII

Wholesale Dealers of Diffusion Furnaces - FeCrAl ocr23al5 high resistance heating strip element for furnace – TANKII Detail:

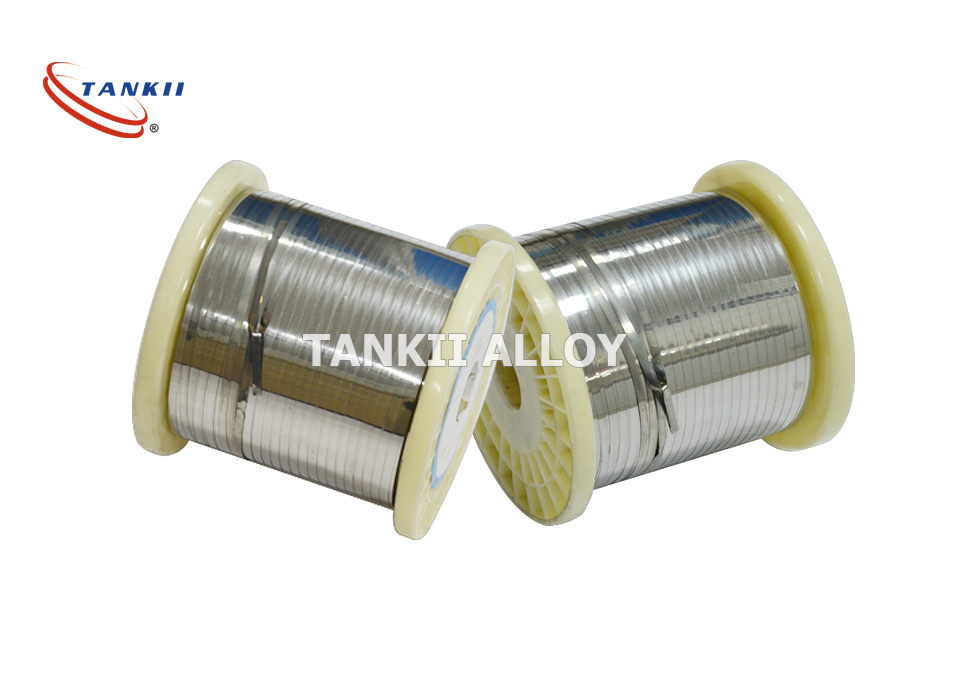

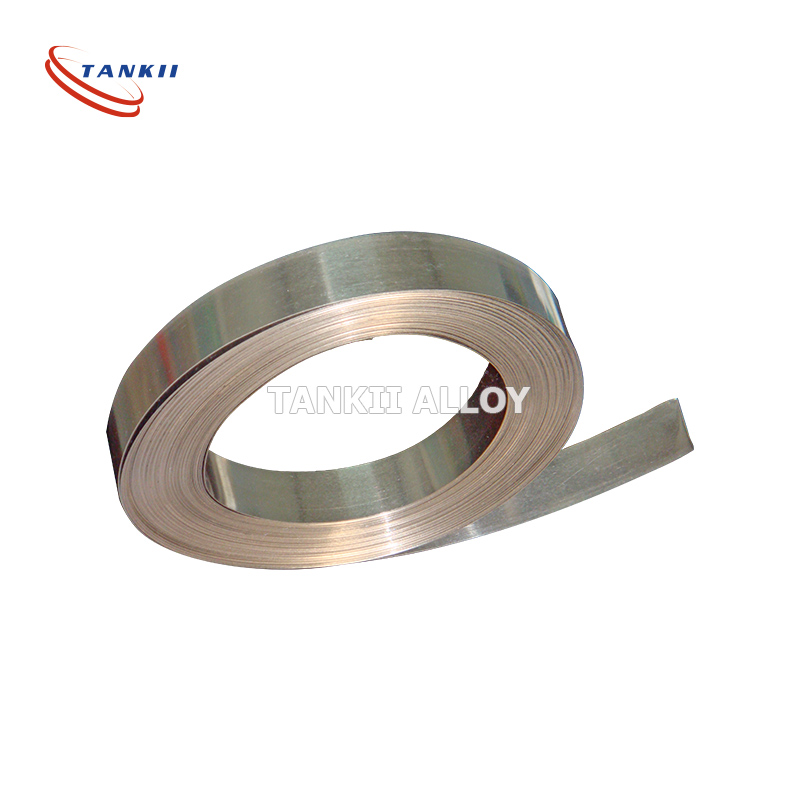

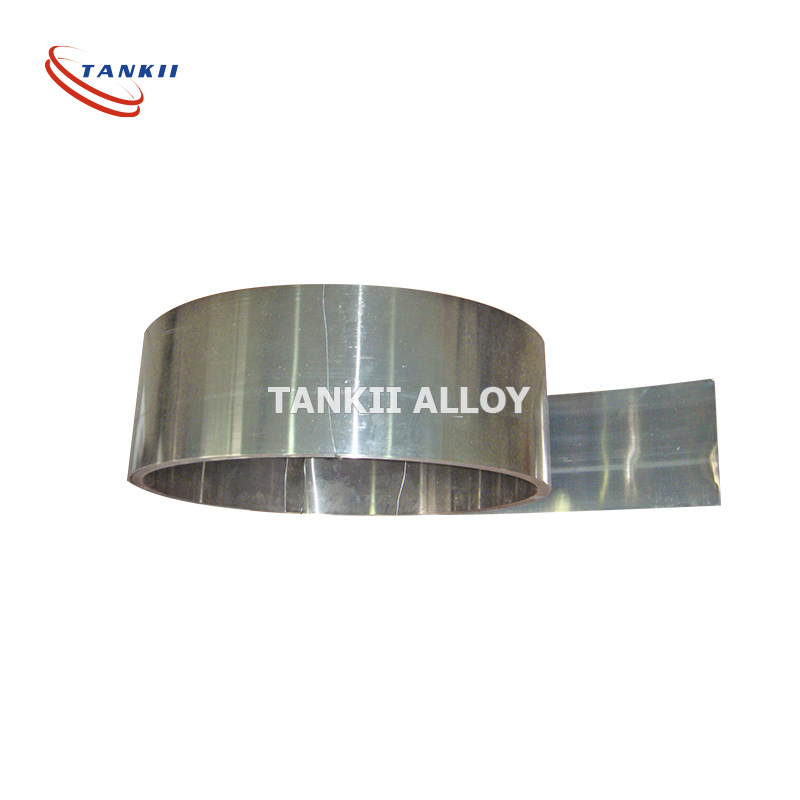

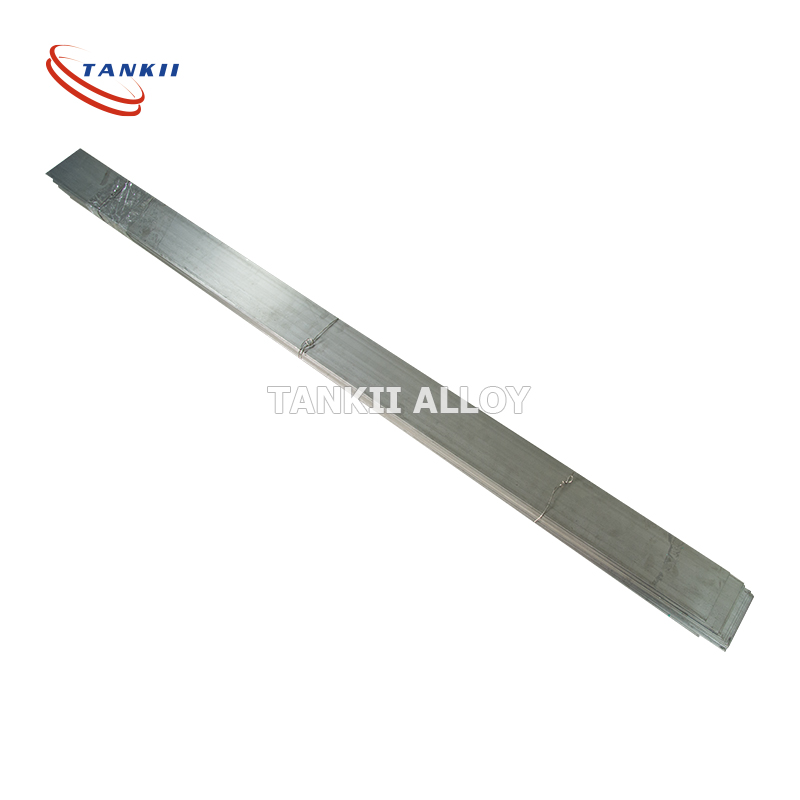

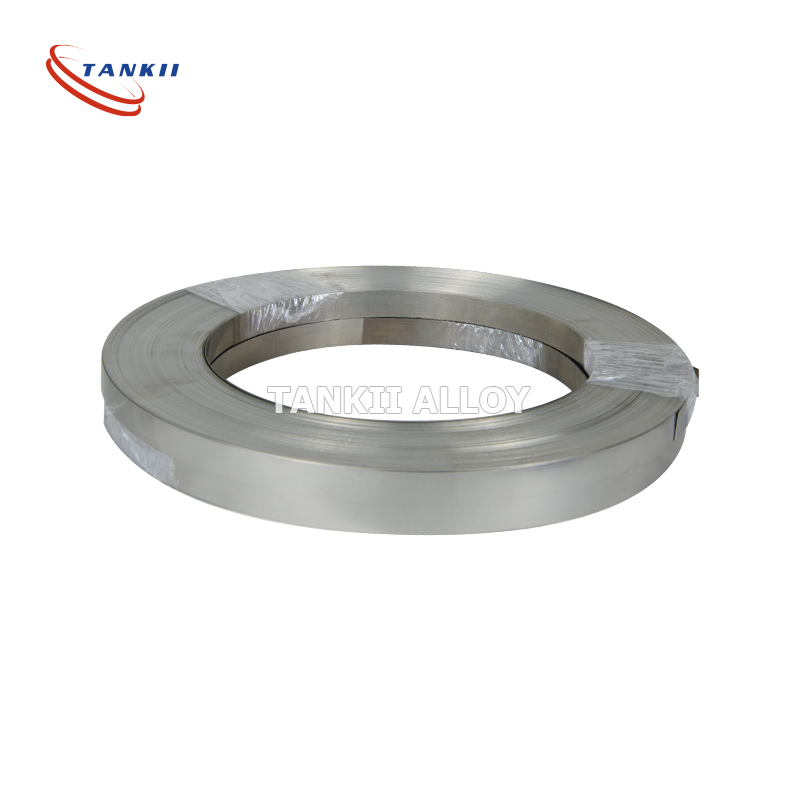

FeCrAl ocr23al5 high resistance heating strip element for furnace

|

Grade

|

0Cr23Al5

|

|

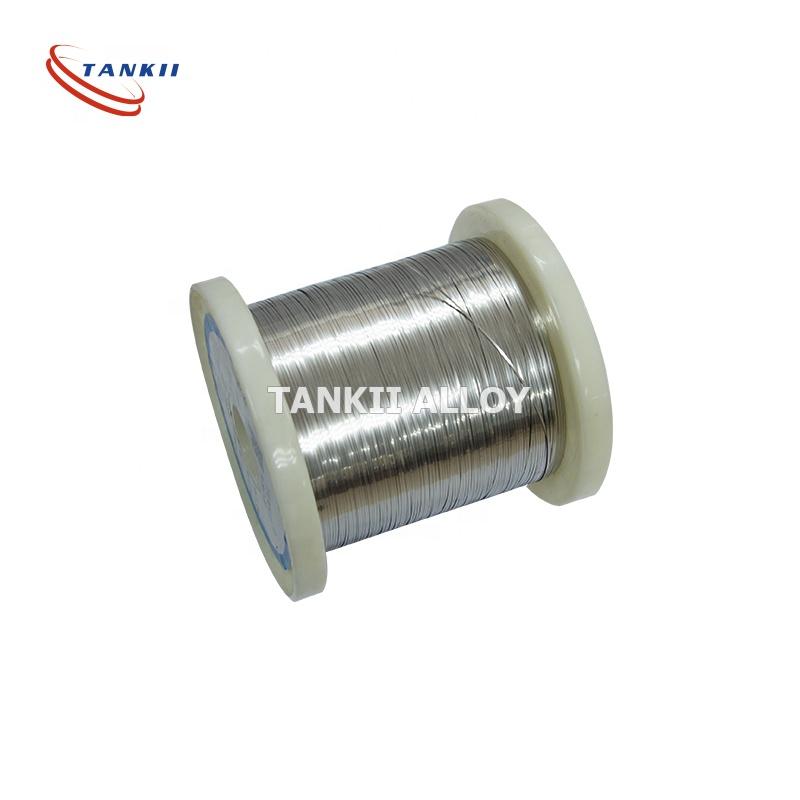

Size

|

thickness:0.05-3mm

width:4-250mm

|

|

Surface

|

bright slitting

|

|

Weight

|

1-3kg/roll ,according customers’ quantity

|

|

Resistivity

|

1.3±0.05μΩ.m

|

|

Hardness(HV)

|

180-210HV

|

|

Elongation

|

≥16%

|

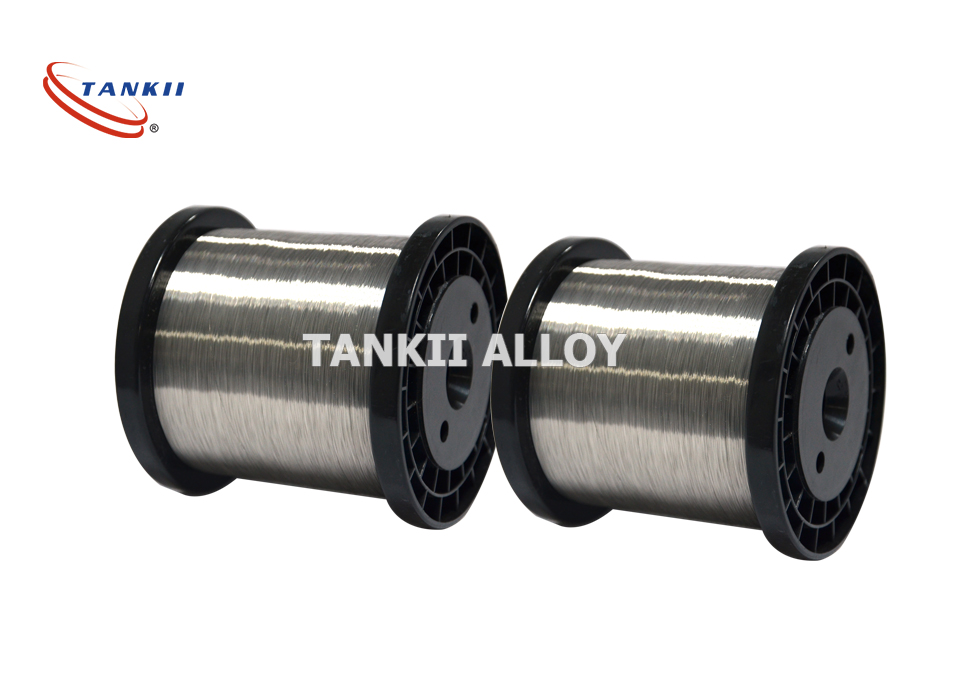

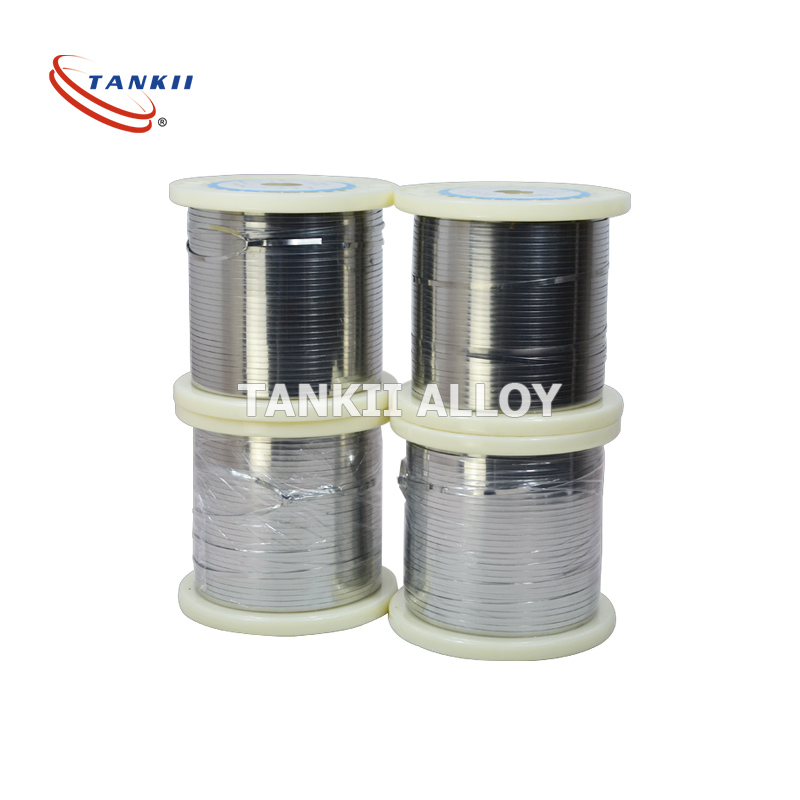

Shanghai Tankii ALloy Material Co.,Ltd. focus on the production of nichrome alloy, thermocouple wire,fecral alloy,precision alloy,copper nickel alloy,thermal spray alloy etc. in the form of wire,sheet,tape,strip,rod and plate.

We’ve already got ISO 9001 quality system certificate and approval of ISO 14001 environmental protection system.We own a complete set of advanced production flow of refining,cold reduction,drawing and heat treating etc. We also proudly have independent R&D capacity.

|

Grade

|

Highest temperature

|

Resistivity

|

Hardness

|

Tensile strength

|

Elongation

|

|

0Cr13Al4

|

1050℃

|

1.25±0.05μΩ.m

|

180-210HV

|

≥550N/mm2

|

≥16

|

|

0Cr15Al5

|

1100℃

|

1.3±0.05μΩ.m

|

180-210HV

|

≥550N/mm2

|

≥16

|

|

0Cr21Al6Nb

|

1300℃

|

1.42±0.05μΩ.m

|

200-240HV

|

750N/mm2

|

≥12

|

|

Cr20Ni80

|

1200℃

|

1.09±0.05μΩ.m

|

180-220HV

|

750N/mm2

|

≥20

|

|

Cr15Ni60

|

1150℃

|

1.12±0.05μΩ.m

|

175-210HV

|

750N/mm2

|

≥20

|

|

Cr20Ni35

|

1100℃

|

1.04±0.05μΩ.m

|

180-220HV

|

750N/mm2

|

≥20

|

|

Cr25Ni20(310S)

|

1100℃

|

0.86±0.05μΩ.m

|

180-220HV

|

750N/mm2

|

≥20

|

|

Grade

|

Chemical composition%

|

||||||||

|

C

|

P

|

S

|

Mn

|

Si

|

Cr

|

Ni

|

Al

|

Fe

|

|

|

≤

|

|||||||||

|

0Cr15Al5

|

0.04

|

0.02

|

0.01

|

0.3

|

≤0.5

|

13-14

|

<1

|

4.8-5.0

|

balance

|

|

0Cr21Al6Nb

|

0.05

|

0.025

|

0.02

|

0.5

|

≤0.6

|

21-23

|

≤0.6

|

5-7

|

balance

|

|

0Cr13Al4

|

0.04

|

0.02

|

0.01

|

0.3

|

≤0.5

|

13-14

|

<1

|

4.8-5.0

|

balance

|

|

Cr20Ni80

|

0.08

|

0.02

|

0.015

|

0.6

|

0.75-1.6

|

20-23

|

balance

|

<0.5

|

≤1.0

|

|

Cr15Ni60

|

0.08

|

0.02

|

0.015

|

0.6

|

0.75-1.6

|

15-18

|

55-61

|

<0.5

|

balance

|

|

Cr20Ni35

|

0.08

|

0.02

|

0.015

|

1.0

|

1-3

|

18-21

|

34-37

|

-

|

balance

|

|

Cr25Ni20

|

0.08

|

0.045

|

0.03

|

2.0

|

0.4-0.6

|

24-26

|

19-22

|

-

|

balance

|

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with Wholesale Dealers of Diffusion Furnaces - FeCrAl ocr23al5 high resistance heating strip element for furnace – TANKII , The product will supply to all over the world, such as: Slovenia, Curacao, Sydney, Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

Write your message here and send it to us